The Paris Agreement adopted in 2015 at the 21st Session of the Conference of the Parties to the United Nations Framework Convention on Climate Change put forward the long-term goal of controlling the rise of average global temperature.

In 2020, President Xi Jinping proposed at the 75th Session of the United Nations General Assembly that by 2030 China will achieve its peak carbon emissions and will strive to achieve the goal of “carbon neutrality” by 2060.

In October 2020, the Central People’s Government of China issued the New Energy Automobile Industry Development Plan (2021-2035), which pointed out that the sales of new energy vehicles (including passenger cars and heavy-duty trucks) in China should reach about 20% of the total sales of new vehicles in 2025 and 40% in 2030.

China’s transportation sector produces 10% of China’s greenhouse gas emissions. low carbon passenger cars are great, but at present, the carbon emissions of passenger cars in China account for only 18% of the total carbon emissions from transportation, and this proportion will continue to decrease in the future. More road transport emissions are from heavy-duty trucks.

At present, China has more than 10 million fuel heavy-duty trucks, generating nearly 1 billion tons of carbon dioxide emissions and nearly 8 million tons of four pollutant emissions (carbon monoxide, hydrocarbons, nitrogen oxides, particulate matter) every year. If about 3 million fuel heavy-duty trucks serving short-distance transportation are replaced by electric heavy-duty trucks, it is estimated that 135 billion liters of diesel consumption, 355 million tons of CO2 emissions and 2.3846 million tons of four pollutant emissions can be saved every year. However, at present, China’s electric heavy-duty trucks cannot be popularized, mainly because the traditional charging method cannot meet the requirements of heavy-duty trucks for continuous operation.

In China, power bank sharing for mobile phones has achieved considerable success, the main reason of which is that it integrates the Internet of Things technologies with the sharing economy. Inspired by this, as the world’s largest clean energy power generation enterprise, the State Power Investment Corporation Limited (SPIC) proposed the design concept and operation mode of Truck-Battery Separation mode (TBS mode), that is, “truck and battery can be used separately, and battery can be swapped quickly”. In line with the original aspiration of realizing low carbon emission of heavy trucks, while building battery-swap facilities, SPIC adapts to local conditions and uses its self-generated electricity (from wind power, photovoltaic, etc.) and purchases green power from the power market to charge batteries for heavy-duty trucks.

The Power Battery Bank for BS electric heavy-duty truck invested and constructed by SPIC can centrally store and operate batteries efficiently and safely. Through this real-time big data platform for battery management and distribution, all heavy-duty truck users can share and rent batteries at any time, and quickly swap batteries at battery-swap stations to complete energy replenishment. Therefore, users don’t have to often worry about the headaches of driving range and battery capacity attenuation. At the same time, users can also enjoy the one-stop services provided by SPIC, such as battery maintenance, life extension, and recycling.

The battery-swap facilities developed by SPIC, which is conducive to the planning and construction, features small size, modularization and mobility and solves the longstanding problem of large floor area of electric heavy-duty truck charging facilities.

At present, battery-swap for heavy-duty truck can be done within as short as five minutes, which has greatly improved the operation efficiency of electric heavy-duty trucks. In addition, the TBS mode reduces the one-time truck purchase cost of heavy-duty truck users (without purchasing battery, truck purchase cost is reduced by 50%). In addition, since the cost of electricity is lower than that of fuel, BS electric heavy-duty trucks are 15% more economical. At the same time, BS electric heavy-duty trucks provide quiet, stable, and comfortable driving experiences, which significantly reduces drivers’ labor intensity, thus making this profession more gender-inclusive.

From the official launch of the project of Battery-Swap electric heavy-duty truck (BS electric heavy-duty truck) in 2018 to the end of 2021, more than 12,000 heavy-duty trucks using SPIC’s battery-swap standards have been promoted, nearly 6,200 trucks have been delivered, and the cumulative operation mileage is nearly 47 million kilometers. If we calculate with a BS electric heavy-duty truck’s annual electricity consumption as 150 MWh, the 12,000 heavy-duty trucks that have been promoted are expected to save 500 million liters of diesel every year, reduce CO2 emissions by nearly 1.5 million tons, and reduce four pollutant emissions by nearly 10,000 tons.

SPIC has helped 19 heavy-duty truck manufacturers in China to develop 42 general models of BS electric heavy-duty trucks and has preliminarily promoted setting local battery-swap standards for commercial new energy vehicles in Inner Mongolia Autonomous Region in northern China, Shandong Province on the east coast of China, and Chongqing Municipality in southwest China, and is helping set Standards of China.

By the end of 2021, the companies participating in the business ecosystem of BS electric heavy-duty truck project initiated by SPIC had applied for 237 technical patents. Several important Chinese media, such as xinhuanet.com and people.com.cn, have had positive reports on the project. Welcome to Green Power Transportation of SPIC’s WeChat official account to keep updated on the latest progress of the project.

| Corresponding Points of ESCI Scoring Mechanism | |||

| S/N | Corresponding Points of ESCI Scoring Mechanism | Corresponding Chapter | Key Illustration |

| I. | Strategy | ||

| 1 | Innovation | ||

| 1.1 | Is the innovative concept come from the project itself or other existing programs? | Chapter II | l The innovative design concept and operation mode of Battery-Swap electric heavy-duty truck (BS electric heavy-duty truck), that is, “heavy-duty trucks with separable batteries that can be swapped quickly”, was put forward by the State Power Investment Corporation Limited (SPIC) for the first time in China.

l In essence, this innovative concept is an integration of Internet of things (IoT) technology and sharing economy. l Such innovative concept is partly enlightened by the Power Battery Bank of mobile phone, which has achieved considerable success in Chinese market. Meanwhile, the innovative concept also cross references and enlightens each other with the battery-swap mode of passenger vehicles, which is promoted synchronously in China. |

| 1.2 | How the innovative policy design encourages financial support and public-private partnership? | Chapter I | l In 2012, the central government of China issued the Development Plan for Energy Saving and New Energy Vehicle Industry (2012-2020), which systematically planned the strategic objectives, tasks and measures of new energy vehicles. In October 2020, the central government of China issued the New Energy Automobile Industry Development Plan (2021-2035), which aims to accelerate the promotion and application of new energy vehicles, especially in public transport such as bus, cab, logistics and distribution, ports, terminals and hubs. The approach has effectively promoted the complemented advantages and extensive cooperation between vehicle operation enterprises and production enterprises in various forms of ownership in China. Meanwhile, it is worth noting that, in this plan, the battery-swap mode has been further recognized and encouraged.

l During the 13 years from 2009 to 2022, China’s central government has provided financial subsidies for the sales of new energy vehicles in the way of “declining year by year”, which fully mobilized the enthusiasm of enterprises for R&D and production, and attracted consumers to embrace the changes in vehicle use and energy consumption habits brought about by new energy vehicles, so as to gradually lead China’s new energy vehicle industry to develop from policy-driven to market-driven mode. l In April 2021, the central government of China launched the pilot program on the application of battery-swap mode of new energy vehicle, and 11 cities were included. Among them, Tangshan City in Hebei Province, Yibin City in Sichuan Province and Baotou City in Inner Mongolia were identified as the pilot city of battery-swap electric heavy-duty truck project. The expected goal of the pilot work is to promote over 100,000 vehicles and establish more than 1,000 battery-swap stations, and the energy conservation and emission reduction amounts to a saving of more than 700,000 tons of fuel and a reducing of more than 2 million tons of carbon per year. |

| 1.3 | How does the innovative concept catch the trend of future development? | Chapter II | The BS electric heavy-duty truck mode represents a way to implement short-distance low carbon transportation in areas with high frequency of cargo transportation such as mines and ports. It fits in with the changes faced by transportation and energy in the future in the following aspects:

l Meet the needs of efficient and low cost vehicle operation: Through the design concept and operation mode of “heavy-duty trucks with separable batteries that can be swapped quickly”, 5-minute battery swap has been achieved to greatly improve the operation efficiency of electric heavy-duty trucks, significantly reduce the cost in vehicle purchase and use, which shows the characteristics of user friendliness. l Provide shared use and management services for power batteries: The Power Battery Banks for BS electric heavy-duty trucks invested and constructed by SPIC can centrally store and operate batteries efficiently and safely. Through this real-time big data platform for battery management and distribution, all BS electric heavy-duty truck users can rent batteries in a sharing mode at any time, and quickly swap batteries at battery-swap stations to complete energy replenishment. Therefore, users don’t need to worry about the headaches of driving range and battery capacity attenuation. At the same time, users can also enjoy the one-stop services provided by SPIC, such as battery maintenance, life extension, and recycling. l Efficient and flexible layout of battery-swap facilities: The battery-swap facilities developed by SPIC, which is conducive to the planning and construction, features small size, modularization and mobility and solves the longstanding problem of large floor area of electric heavy-duty truck charging facilities. l Full application of IoT and big data technology: The battery sharing service and quick battery-swap service for BS electric heavy-duty trucks are provided with digital guarantee by a set of IoT system independently developed by SPIC, which can monitor and trace the whole life cycle of the battery and its system to ensure its safety. Meanwhile, the massive traffic and energy big data accumulated by the platform can simultaneously empower different participants, such as vehicle operators, battery-swap station operators and government regulatory authorities improve fleet scheduling and operation, optimize the layout of transportation and energy infrastructure and promote the construction of smart cities. l Expected to truly achieve low carbon emission of heavy-duty truck transportation: As the world’s largest clean energy power generation enterprise, SPIC proposed the design concept and operation mode of BS electric heavy-duty truck, that is, “heavy-duty trucks with separable batteries that can be swapped quickly”. In line with the original aspiration of realizing low carbon emission of heavy trucks, while building battery-swap facilities, SPIC could use its self-generated electricity (from wind power, photovoltaic, etc.) in accordance with local conditions, and purchase green power from the power market to charge batteries for heavy-duty trucks. |

| 2 | Enlightening | ||

| 2.1 | Whether the idea can inspire later/subsequent cases? | Chapter IV | Yes.

l By the end of 2021, more than 12,000 BS electric heavy-duty trucks using SPIC’s battery-swap standards have been promoted, nearly 6,200 trucks have been delivered, and the cumulative operation mileage is nearly 47 million kilometers. In the scenes of internal transportation of open-pit coal mines in Inner Mongolia in North China, delivery transportation of steel-making enterprises in Tangshan, Hebei Province, the “world steel capital” in North China, transportation in Zhoushan port, Ningbo, Zhejiang Province, the world’s largest container port in East China, and coal transportation of thermal power plants in Guizhou Province in Southwest China, the large-scale application of BS electric heavy-duty truck has been realized and played an exemplary role in promoting the innovative concept to similar scenes in other regions. l SPIC has helped 19 heavy-duty truck manufacturers in China to develop 42 series of general BS electric heavy-duty trucks with battery-swap functions, based on which 176 models of BS electric heavy-duty trucks with battery-swap functions have been launched. Meanwhile, SPIC has preliminarily promoted setting local battery-swap standards for commercial new energy vehicles in Inner Mongolia Autonomous Region in northern China, Shandong Province on the east coast of China, and Chongqing Municipality directly under the central government in southwest China, and is helping set Standards of China. |

| 2.2 | What domain has been enlightened by this policy? | Chapter I | l It can be predicted that with the release of the Development Plan for Energy Saving and New Energy Vehicle Industry (2012-2020) and the launch of the pilot application of new energy vehicle battery-swap mode, the production and sales of new energy vehicles in China will maintain a sustained and rapid growth, the application of BS electric heavy-duty trucks used in mines, steel plants, thermal power plants, ports, urban muck transport and other short-distance continuous transportation scenarios will be accelerated, and the establishment of Technical Standards of China for battery swap of new energy commercial vehicles will be sped up.

l The layout of battery-swap infrastructure will be improved. Enterprises of different ownership types will jointly participate to invest and construct battery-swap infrastructure and serve users of BS electric heavy-duty trucks through a unified information platform to meet users’ rigid demand for vehicle energy supply efficiency. l Related industrial policy will further support the “Power Battery Bank” mode and encourage on-demand rental services to vehicle users through the sharing economy. “Power Battery Bank” carries out data monitoring, maintenance services, centralized recycling and echelon utilization of battery life cycle, and build and improve the whole life cycle management of power battery, a new industry chain. |

| 3 | Definition | ||

| 3.1 | Is there any open and transparent channel of public communication? | Chapter V | Yes.

l Several important Chinese media, such as Xinhuanet.com and People.com.cn, have had positive reports on SPIC’s BS electric heavy-duty truck project. l SPIC has created its social media account such as WeChat official account “Green Power Transportation” as a regular external exchange window to periodically release information about the relevant mode concepts, R&D, project cases, social benefits of energy-saving and emission reduction related to the BS electric heavy-duty truck project. l SPIC has actively participated in various exhibitions and activities such as Guiyang Industrial Expo, China-Northeast Asia Expo and various industries forums to have face-to-face communication with industrial partners and users. |

| 3.2 | Is there any difference between this policy and other similar policies? | Chapter V | Yes.

China’s central and local governments jointly promote the governance of carbon emissions through a multi-dimensional policy combination, namely, the “multi-pronged approach”. In Tangshan, Hebei Province, the “world steel capital”, local government implements strict environmental protection performance assessment for local steelmaking enterprises, and takes the proportion of clean transportation in outbound transportation of steel-making enterprises as a rigid indicator. The environmental protection performance assessment will directly determine the production capacity that can be released by each steel-making enterprise, which links the carbon emission of transportation with the business benefits of the enterprise, so as to push the enterprise to actively carry out the transformation of clean transportation. |

| II. | Measures | ||

| 4 | Feasibility | ||

| 4.1 | Has any effective measure for moving ahead been made? | Chapter IV | Yes. The BS electric heavy-duty truck project is promoted with clear approaches and plans.

l In 2018, SPIC put forward the conceptual design of the BS electric heavy-duty truck project, successfully led the R&D of the BS electric heavy-duty truck model and built the world’s first battery-swap demonstration station for heavy-duty trucks. l In 2019, SPIC officially started the scaled promotion of BS electric heavy-duty trucks, constructed Power Battery Banks and laid out the network of battery-swap stations. l In 2020, contracts of 5,400 BS electric heavy-duty trucks applying SPIC standards were signed, and 1,150 were delivered. l By the end of 2021, more than 12,000 heavy-duty trucks using SPIC’s battery-swap standards have been promoted, 6,200 trucks have been delivered, the Power Battery Bank has invested in 1.86GWh of power battery assets, and nearly 70 battery-swap stations have been built. |

| 4.2 | Are there any numerical goals for reference? | 2, Chapter IV | Yes. SPIC has set clear quantifiable goals for the promotion of BS electric heavy-duty truck project.

l 2025 target: By the end of 2025, SPIC aims to promote the delivery of 200,000 BS electric heavy-duty trucks (on SPIC technical standards), the Power Battery Bank will hold and operate 64.3 GWh of power batteries, 4,000 battery-swap stations will be built and provide public service in form of networking operation. l Medium- and long-term target: among the 10 million diesel heavy trucks currently held in China, SPIC plans to replace 3 million trucks engaged in short-distance continuous transportation with BS electric heavy-duty trucks. |

| 5 | Replicability | ||

| 5.1 | Could the ideas, methods or techniques be applied internationally? | Chapter V | Yes, the products and operation mode of BS electric heavy-duty trucks can be widely used all over the world.

l In any region in the world, as long as there are scenes of short-distance road transportation such as mining areas and ports, and a leading enterprise similar to SPIC to lead the promotion of BS electric heavy-duty trucks, the construction of Power Battery Bank, the layout of battery-swap facilities and the erection of cloud service platform, the replicated application of BS electric heavy-duty trucks can be realized quickly. l As a traditional means of transportation, heavy trucks have been highly popular. The application of BS electric heavy-duty trucks will not significantly change the original logistics and transportation system and is easy to be accepted by these industries. l The promotion and application of BS electric heavy-duty trucks will not put forward harsh requirements for changes to the existing land, roads and other infrastructure. Only stable power supply and mobile Internet are needed to implement the normal operation of BS electric heavy-duty trucks and battery-swap stations. |

| 6 | Cost-effectiveness | ||

| 6.1 | Will it be cost-effective to implement? | Chapter V | Yes, compared with the charging mode of electric heavy-duty trucks and the traditional fuel heavy-duty trucks, BS electric heavy-duty trucks can achieve significant cost-benefit advantages in purchase and use.

l Purchasers of BS electric heavy-duty trucks do not need to buy the power battery. Compared with a complete electric heavy truck with the same specification, the purchase cost will be reduced by 50%. l The purchase cost of a BS electric heavy-duty truck is the same as that of a fuel heavy-duty truck of the same specification. However, the former does not need engine maintenance or urea addition, so the vehicle operation cost will be reduced. l The comprehensive energy use cost is 15% – 30% lower than that of traditional fuel heavy-duty trucks by renting power batteries and purchasing battery-swap services. |

| 6.2 | Is there any measurable reduction of emission or energy use? Please describe the measurement method. | Chapter I

Chapter VI |

Yes.

l According to the highway standard load operation condition, the average diesel consumption of traditional diesel heavy truck is about 0.45 L/km, while the average power consumption of BS electric heavy-duty trucks is about 1.5 kWh/km. According to the calculation that a heavy-duty truck travels 100,000 kilometers a year, the annual diesel consumption of a traditional heavy-duty truck is 45,000 liters, and the annual electricity consumption of a BS electric heavy-duty truck is 150 MWh. Thus, replacing 3 million diesel trucks with BS electric heavy-duty trucks could save 135 billion liters of diesel per year. l According to the calculation that consuming 1 liter of diesel will produce 2.63 kg CO2, if 3 million diesel heavy trucks are replaced with BS electric heavy-duty trucks, the CO2 emission can be reduced by about 355 million tons per year. l According to the total emission of four pollutants from heavy trucks calculated by the Ministry of Ecology and Environment of China, if 3 million diesel heavy trucks are replaced with BS electric heavy-duty trucks, the emission of four pollutants can be reduced by 2.3846 million tons per year. |

| 7 | Consistency | ||

| 7.1 | Are adopted measures consistent with energy policy and strategy? | Chapter I | Yes, the BS electric heavy-duty truck project is consistent with many energy policies and strategic directions of APEC and China.

1. In line with energy conservation and emission reduction policies: l In line with the long-term goal of controlling the rise of average global temperature set out in the Paris Agreement. l In line with China’s development goal of “reaching the peak of carbon dioxide emissions by 2030 and striving to achieve ‘carbon neutrality’ by 2060”. l In line with the strategic direction of promoting energy conservation and emission reduction and fighting a tough battle of pollution prevention and control in the China’s Comprehensive Work Plan for Energy Conservation and Emission Reduction in the 14th Five-Year Plan. 2. In line with the automobile industry development policy: l In line with the development direction of global new energy vehicle industry. l In line with the direction of “promoting the high-quality development of new energy vehicle industry” pointed out in the New Energy Automobile Industry Development Plan (2021-2035) issued by China’s central government department. |

| 7.2 | Is there any long-term measure or implementing organization for this project? | Chapter VI | Yes.

As the long-term implementor of the project, SPIC has made it clear at the press conference of the 2020 social responsibility report that by the end of 2025, it will deliver 200,000 BS electric heavy-duty trucks (on SPIC technical standards), the Power Battery Bank will hold and operate 64.3 GWh of power batteries, and 4,000 battery-swap stations will be built and provide public service in form of networking operation. |

| III | Demonstration | ||

| 8 | Completeness | ||

| 8.1 | Is the achievement scale measurable? | Chapter IV | Yes.

l The promotion progress of the BS electric heavy-duty truck project can be measured by the following data: Ø Sales contract volume and delivery volume of BS electric heavy-duty trucks adopting the SPIC technical standards. Ø The number of sets of power battery assets and installed capacity held and operated by the Power Battery Bank. Ø Network layout of battery-swap facilities. Ø Number of shared power battery assets and battery-swap stations accessed to the IoT platform of SPIC. l Meanwhile, the cumulative discharge of the power battery can be converted into equivalent diesel consumption to measure the savings of diesel consumption caused by replacing the traditional diesel heavy-duty trucks with BS electric heavy-duty trucks, and further calculate the carbon dioxide and four pollutant emission reductions caused by the reduction of diesel consumption to measure the environmental protection value of the project. |

| 8.2 | Will it make a considerable success in project goals? | Chapterssta IV | Yes.

l At the press conference of 2020 social responsibility report, SPIC has clearly put forward the promotion goal of battery-swap project by the end of 2025, which not only confirms the original intention of SPIC as the world’s largest clean energy power generation enterprise to promote green development in transportation, but also reflects its social responsibility as a Chinese central enterprise. l By the end of 2025, a total of 200,000 BS electric heavy-duty trucks will replace the traditional diesel heavy-duty trucks, which will save 9 billion liters of diesel every year, corresponding to 23.67 million tons of carbon dioxide emissions and 159,000 tons of four pollutants. l Meanwhile, SPIC is helping to form China’s Technical Standards of China for battery swap of new energy commercial vehicles and promote the replacement of all short-distance diesel heavy-duty trucks for continuous transportation in China with BS electric heavy-duty trucks. |

| 9 | Verifiability | ||

| 9.1 | Is there any data presented to support the project? | Chapter IV | Yes.

By the end of 2021, the following progress has been made in the BS electric heavy-duty truck project: Among all 218 models of BS electric heavy-duty trucks registered and allowed to be put on the market by China’s central government departments, there are 176 models using the SPIC technical standards, accounting for 80%. l In China, more than 12,000 BS electric heavy-duty trucks using SPIC’s battery-swap standards have been promoted, nearly 6,200 trucks have been delivered, and the cumulative operation mileage has reached nearly 47 million kilometers. l The Power Battery Bank established by SPIC has invested in 1.86GWh of power battery assets. l More than 600 battery-swap stations have been surveyed in total, and 70 stations have been arranged in 31 provinces, autonomous regions and municipalities in China. |

| 9.2 | Is there any supportive measurement or reference for the provided data? | Chapter II | Yes.

The intelligent hardware equipment and the IoT platform independently developed by SPIC can accurately collect the data of BS electric heavy-duty trucks adopting SPIC technical standards, power batteries operated by Power Battery Banks and battery-swap facilities, so as to realize the real-time monitoring of the operation of the above assets and the traceability of operation. The big data generated by the IoT platform can support the implementation results of the project. |

| 10 | Influence | ||

| 10.1 | Will it make a significant change in the field of energy efficiency and energy saving? | Chapter I

Chapter VI Chapter VII |

Yes.

At present, China has more than 10 million fuel heavy-duty trucks, generating nearly 1.2 billion tons of carbon dioxide emissions and nearly 8 million tons of four pollutant emissions (carbon monoxide, hydrocarbons, nitrogen oxides, particulate matter) every year. If about 3 million fuel heavy-duty trucks serving short-distance transportation are replaced by BS electric heavy-duty trucks, it is estimated that 135 billion liters of diesel consumption, 355 million tons of CO2 emissions and 2.3846 million tons of four pollutant emissions can be saved every year. |

| 10.2 | Will it impact multiple operational areas or just single specific area? | Chapter III

Chapter IV Chapter V |

The project is not limited to specific regions and scenes, and replication will be promoted worldwide.

l The application of BS electric heavy-duty truck is not limited to specific scenarios. It is applicable to a variety of short-distance continuous transportation scenarios such as ports, steel plants, mines, power plants and urban residue transportation. With the improvement of the layout of battery-swap infrastructure, the use of BS electric heavy-duty trucks will be extended to long-distance trunk transportation. l The application of BS electric heavy-duty trucks in the above scenarios is not only for specific regions. At present, SPIC has carried out vehicle operation in 31 provinces, autonomous regions and municipalities in China, and the project results have been fully verified. l The mode of BS electric heavy-duty truck has no strict requirements for infrastructure transformation and will not change the original logistics and transportation system, which is conducive to the global replication and promotion of this mode. |

| 11 | Inclusiveness | ||

| 11.1 | Is it gender inclusive or not? | Chapter V | Yes.

BS electric heavy-duty trucks feature low noise, no pollution, comfortable driving experience and great improvement of working environment in the trucks, which significantly reduce drivers’ labor intensity, thus making this profession more gender inclusive. |

I. Background

1. Target of 1.5℃ temperature control and innovative development of new energy vehicles

The Paris Agreement, adopted at the 21st United Nations Climate Change Conference (Paris Climate Conference) on December 12, 2015, sets out a long-term goal to control the rise in global average temperature, agreeing to a level of temperature rise of no more than 2℃ compared with that in the period before industrialization and joint efforts to keep the level of temperature rise within 1.5℃.

In 2020, President Xi Jinping proposed at the 75th Session of the United Nations General Assembly that by 2030 China will achieve its peak carbon emissions and will strive to achieve the goal of “carbon neutrality” by 2060.

Globally, transportation accounts for 14% of all greenhouse gas emissions. There is an urgent need to reduce carbon emissions in the transportation sector, and new energy vehicles are being promoted at an accelerated pace worldwide. In October 2020, the Central People’s Government of China issued the New Energy Automobile Industry Development Plan (2021-2035), which pointed out that the sales of new energy vehicles (including passenger cars and Heavy-Duty Trucks) in China should reach about 20% of the total sales of new vehicles in 2025 and 40% in 2030.

China’s transportation sector produces 10% of China’s greenhouse gas emissions. low carbon passenger cars are great, but at present, the carbon emissions of passenger cars in China account for only 18% of the total carbon emissions from transportation, and this proportion will continue to decrease in the future. More road transport emissions are from Heavy-Duty Trucks. At present, there are more than 10 million fuel Heavy-Duty Trucks in China, of which about 3 million serve short-distance transportation. The electric energy replacement of 3 million fuel Heavy-Duty Trucks will annually save 135 billion liters of diesel consumption, reduce CO2 emissions by about 355 million tons and reduce emissions of four pollutants by a total of 2.38 million tons.

Under the increasing pressure of energy security and environmental protection, the transformation from fuel vehicles to new energy vehicles has become a strategic initiative for transforming and upgrading the global automobile and energy industries. In 2014, the 11th APEC Energy Ministers’ Meeting put forward the goal of “doubling the proportion of renewable energy and its power generation in the regional energy structure in the APEC region by 2030 compared with 2010”. To achieve these goals and effectively promote energy transition in the Asia-Pacific region, the APEC Sustainable Energy Center (APSEC) has proposed to implement the pillar projects of the Energy Transition Solutions (ETS) in the Asia-Pacific region from 2020. In the ETS, APSEC advocates that member states support innovative R&D in related green transportation industries, including electric vehicles.

In April 2021, the Ministry of Industry and Information Technology of the People’s Republic of China and the National Energy Administration decided to jointly organize the pilot work on the application of the battery-swap mode for new energy vehicles, aiming to implement the New Energy Automobile Industry Development Plan (2021-2035) and promote the innovative application of the battery-swap mode for new energy vehicles and the in-depth integration and development of new energy vehicles and energy, so as to form a healthy development ecology with complementary charging and battery-swap modes for new energy vehicles.

2. TBS mode – an effective path to solve the carbon emission of Heavy-Duty Trucks

(1) Status of the industry of Battery-Swap Electric Heavy-Duty Truck

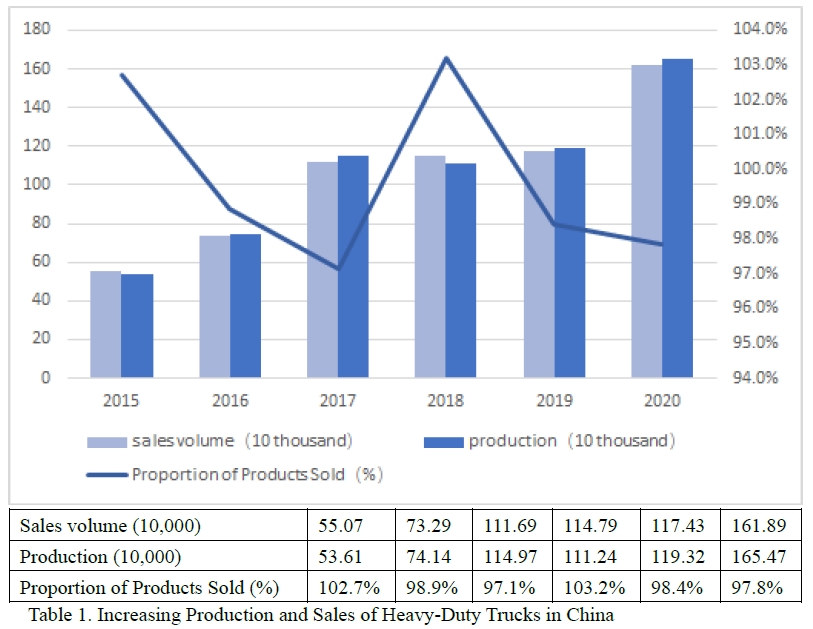

With the increasing concentration of the logistics industry, the proportion of large fleets and corporate customers has increased significantly, and the demand for Heavy-Duty Trucks has been rising. According to statistics, about 10 million Heavy-Duty Trucks are in the Chinese market. The data shows that one Heavy-Duty Truck’s emission equals that of 300 cars.

The industrialization promotion and application of new energy vehicles in China started in 2009, and the current scale of the industry is world-leading. The production and sales have ranked first in the world for five consecutive years, with a total of more than 4.5 million vehicles promoted, accounting for more than 50% of the world. Many domestic enterprises of Heavy-Duty Trucks have launched new energy Heavy-Duty Trucks, which has started a new round of technological innovation in the Heavy-Duty Truck industry. The future development of Heavy-Duty Trucks will be more energy-saving and environmentally friendly.

Based on the sales of vehicles in China from 2016-2021, and a conservative estimate of the previous replacement rate (80%) of Heavy-Duty Trucks, the demand for Heavy-Duty Trucks will exceed 500,000 per year for the next five years, without considering the increase in transportation demand. With the maturity of technology for new energy Heavy-Duty Trucks and the improvement of supporting facilities, the advantages of energy saving and environmental protection, higher economy and other advantages will guide consumers to move to new energy Heavy-Duty Trucks.

With the continuous update and development of technology for new energy vehicles, there is a fierce competition between natural gas, hydrogen energy, electric energy and gasoline technology paths. The Truck-Battery Separation mode (TBS mode) that “truck and battery can be used separately, and battery can be swapped quickly” is receiving attention from the market and government departments. Battery swapping is a fast-charging method for new energy vehicles. It has the advantages of fast recharging, high level of automation and integration, which can significantly reduce consumers’ mileage anxiety. It can help to realize “separate sales of body and battery” to solve the problem of high cost of purchasing a car for consumers. Due to factors such as non-uniform standards of battery swap and few battery-swap modes, the development of the battery-swap mode for new energy vehicles is relatively slow. With the financial subsidies declining, the battery-swap mode has regained the attention of government departments and industry enterprises.

The battery-swap mode of Heavy-Duty Truck is in a market stage where opportunities and challenges coexist. The main challenges are: ① The battery swap solutions of different manufacturers are not unified; ② The infrastructure network of the battery-swap station has not been established; ③ It is difficult to approve the land and power capacity required for the construction of the battery-swap station for Heavy-Duty Trucks, and the scale effect of the operation of the battery-swap station is still gradually taking shape; ④ Power battery assets are held by the “Power Battery Bank”, which requires strong capital strength and excellent battery monitoring, management and maintenance programs, and a mature operating mode is urgently needed to realize the full life cycle value chain of power battery echelon utilization and recycling.

In this context, State Power Investment Corporation Limited (SPIC) has embodied the role of China’s government owned enterprises by collaborating with upstream and downstream enterprises to carry out research, development and integration of BS electric heavy-duty truck, as well as mode studies. At the beginning of 2019, the battery-swap tractors developed by State Power Investment and its partners began to enter the market one after another. In March 2020, the BS electric heavy-duty trucks were delivered in batches, and nearly 10,000 BS electric heavy-duty trucks have been successfully put into the market so far. At present, most of the OEMs in China have adopted the battery swap solutions promoted by the SPIC. Under the promotion of multiple parties, the battery-swap mode of Heavy-Duty Trucks is gradually maturing, and the product models are becoming more and more abundant. It is expected that more widespread application will be achieved in 2022 and the scale of demonstration operation will gradually expand.

(2) Status of the Power Battery Bank industry

The TBS mode is an emerging mode of operation for the new energy vehicle industry, and China is at the forefront of the world in exploring this mode. In the battery-swap mode, the power battery has the characteristic of “separable”, and the operation mode of Power Battery Bank can fully meet the needs of the capital market.

In terms of passenger cars, Wuhan Weineng, a representative enterprise in China, specialized in battery asset management and battery rental services in August 2020. NIO sells its cars with the battery packs sold directly to battery asset management companies and consumers purchase bodies of new energy vehicles without batteries. Consumers rent battery packs from battery asset management companies and swap batteries through NIO battery-swap stations. Battery asset management companies are responsible for daily battery management, energy storage and other businesses, while car companies are responsible for battery swap services and consumer connection, achieving a division of labor to improve efficiency.

In terms of commercial Heavy-Duty Trucks, SPIC is a pioneer in the innovation and practice of Power Battery Bank, providing customers with comprehensive package solutions such as the construction of battery-swap stations, rental of on-board battery swaps, operation and maintenance, full life cycle management, and echelon utilization value recovery. SPIC has developed a relatively complete and scientific operation mode of “truck and battery can be used separately, and battery can be swapped quickly”, and has created several pilot projects for mass commercial applications in China. Combined with the application scenarios of BS electric heavy-duty trucks, SPIC strives to create a closed loop of the operation ecology of BS electric heavy-duty trucks.

II. Operation Mode Based on “BS electric heavy-duty truck – Power Battery Bank – Battery-Swap Station”

In China, power bank sharing for mobile phones has achieved considerable success, the main reason of which is that it integrates the Internet of things (IoT) technologies with the sharing economy. Inspired by this, as the world’s largest clean energy power generation enterprise, the State Power Investment Corporation Limited (SPIC) proposed the TBS mode, that is, “truck and battery can be used separately, and battery can be swapped quickly”. In line with the original aspiration of realizing low carbon emission of Heavy-Duty Trucks, while building battery swapping facilities, SPIC adapts to local conditions and uses its self-generated electricity (from wind power, photovoltaic, etc.) and purchases green power from the power market to charge batteries for BS electric heavy-duty truck.

In the TBS mode, the power battery is a mobile energy storage device that can be separated from the body, and its data can be monitored. It can be purchased, leased, transported and managed independently of the car. Truck users only need to purchase an intelligent unpowered body with swappable batteries at one time. They can save battery costs by renting battery packs for battery swap and purchasing charging and swapping services. They can also achieve efficient and uninterrupted operation by quickly swapping batteries at battery-swap station. The Power Battery Bank for BS electric heavy-duty truck constructed by SPIC can centrally hold and operate power batteries efficiently and safely.

1. Vehicle R&D: highly standardized and generalized body of BS electric heavy-duty truck

Over the past few years, the Chinese domestic Heavy-Duty Trucks market has been highly concentrated, and the sales of the top ten companies have always accounted for more than 90% of the industry’s sales, forming an absolute advantage in the market. Therefore, SPIC has cooperated with leading enterprises in R&D from the R&D stage to set standards in battery specifications and communication to maintain consistency, ensuring the full compatibility of different OEMs, different Heavy-Duty Truck models, and batteries of different capacities.

By adopting a powertrain system, power battery system and power exchange mechanism, which are of high performance, high reliability and long life, the overall reliability of BS electric heavy-duty truck is guaranteed. SPIC has joined hands with mainstream Heavy-Duty Truck OEMs at home and abroad to conduct model R&D. So far, it has taken the lead in the R&D of more than 42 BS electric heavy-duty trucks. The products fully match the electrification application needs of short-distance transportation such as power plants, ports, steel mills, mining areas, urban muck, and cement mixing.

2. Battery management: realize the traceability and value maximization of battery life cycle

With the advent of electrification, the power battery has become the cost center, safety center, essential data production center, and electric vehicles energy storage center. There are many key links in the whole life cycle of power batteries. Through the exploration of technology and mode innovation in the main links of R&D, production and use, the synergistic development of each link has been continuously strengthened and the new business form has been evolving.

SPIC has joined hands with mainstream battery manufacturers to develop various battery systems under one united standard. Meanwhile, it has set up a specialized Power Battery Bank to carry out the shared operation of swappable batteries, flexibly matching the multi-scenario and diversified range needs of vehicles. Users can flexibly select and switch services on demand through the online platform. The flexibly swappable battery is no longer a simple onboard component, but a mobile energy storage device. With the Power Battery Bank as a battery management operator, power batteries are safer and more controllable, and truck users no longer have to worry about the attenuation problem of battery capacity. At the same time, they can also enjoy one-stop services such as battery maintenance, life extension and recycling provided by SPIC promptly.

Besides, through the R&D of intelligent equipment and intelligent cloud platform, effective monitoring and analysis of the whole life cycle of battery assets can be realized, and the potential value of its derived transportation and energy big data can be explored, providing essential data support for the continuous iteration of battery technology, continuous optimization of battery cost, improvement of battery safety management and control, the establishment of dynamic assessment standard of battery value, and opening up of echelon utilization channels, etc.

3. Flexible networking: networked layout of efficient and reliable charging and swapping infrastructure

The charging and battery-swap station is the center of energy supply, and its layout is the basis for the promotion of BS electric heavy-duty trucks. Public charging and battery-swap stations in logistics and transportation hubs can provide efficient and fast charging and swapping services for passing vehicles, improve the efficiency of energy supplementation, and promote the organized, large-scale and networked operation of intra-regional and cross-regional battery swapping vehicles.

Since 2016, SPIC has conducted in-depth research on BS electric heavy-duty trucks market through investment and financing services and served terminal operation customers. After four generations of iterative upgrades of battery swapping technology, the final solution is a top lifting battery swapping solution with high efficiency and low system cost to meet the needs of continuous operation with Heavy-Duty Trucks. At the same time, SPIC has innovatively developed a series of charging and battery-swap products with high mobility, such as mobile swapping vehicles, pre-assembled charging bins, mobile battery distribution vehicles and modular skid-mounted battery-swap stations, which are complementary to the products of fixed battery-swap station. The products can also cope with the constraints of power capacity and land scarcity faced by the layout of fixed battery-swap stations, and the product portfolio and deployment plan can be flexibly chosen according to the specific conditions of the business, making the layout of the battery-swap station network more flexible.

•

•

4. Intelligent interconnection: the superimposed application of IoT platform and big data technology

The battery sharing service and fast battery swapping service of BS electric heavy-duty truck are digitally guaranteed by a set of IoT system developed by SPIC, which can monitor and trace the battery system throughout its life cycle to ensure the safety of battery use. Moreover, the massive transportation and energy big data accumulated by the platform can simultaneously empower different participants such as vehicle operators, operators of battery-swap stations and government regulators, to improve the scheduling and operation levels of the fleet, optimize the layout of transportation and energy infrastructure, and promote the construction of smart cities.

The IoT cloud platform mainly covers the monitoring and scheduling cloud platform of connected vehicles, Power Battery Bank cloud platform and management and trading cloud platform for charging and battery-swap stations. These cloud platforms are required for the operation of trucks, batteries and battery-swap stations of BS electric heavy-duty trucks, forming an overall cloud service ecosystem driven by digitalization:

(1) Power Battery Bank cloud platform. Realize the cloud-based transaction settlement of battery leasing business, fully exploit the value of battery information big data, and realize the full life cycle management from use to retirement; at the same time, realize the battery management such as battery operation and maintenance, abnormal state warning, etc. to guarantee the safety of battery use.

(2) Management and trading cloud platform for battery charging and swapping. Through centralized access management and control of charging and battery-swap stations and in-depth interaction with the Power Battery Bank cloud platform, the real-time cloud settlement of charging and battery swapping transactions is realized, and the customer’s experience of service is improved.

(3) Monitoring and scheduling cloud platform of connected vehicles. Realize real-time online monitoring of vehicle positioning, driving trajectory, driving behavior, charging and discharging energy consumption and other information, and enable vehicle operating companies to improve the level of vehicle operation and scheduling. Can be integrated with the production scheduling system and non-truck carrier platform of vehicle usage scenarios to create a green and smart supply chain. Can integrate autonomous driving technology to provide basic platform support for unmanned operations in ports, mines and other scenarios.

III. From Mines, Power Plants to Ports and Docks – BS electric heavy-duty trucks Are Building a New Operation Mode of Heavy-Duty Trucks in China

BS electric heavy-duty trucks focus on the transportation segment of “heavy load and high-frequency”, mainly serving the scenarios such as power plants, mining areas, steel and aluminum plants, ports and urban public services.

1. Power plant scenario

In the business scenario of transporting thermal coal, fly ash, cinder and gypsum required by coal-fired power plants and thermal power plants, there is a large amount of replacement space for BS electric heavy-duty trucks.

2. Mine scenario

In various large-scale open-pit mining areas, there are a large number of heavy mining trucks, 8×4 dump trucks and loaders operating in the state of high frequency, low speed and heavy load. The vehicles require high efficiency for continuous operation. Besides, the energy consumption of the traditional fuel trucks is extremely high due to the harsh working conditions. The cost of energy consumption will be significantly reduced after the traditional fuel trucks are replaced with BS electric heavy-duty trucks. In the process of external transportation of minerals, there are scenarios of “railway/waterway mainline transportation + short-distance vehicle feeder”, in which the Heavy-Duty Trucks used in short-distance feeder lines are also suitable to be replaced by BS electric heavy-duty trucks.

3. Heavy industry scenarios such as steel and aluminum plants

In steel smelting, aluminum plants and other factory areas, there are a large number of closed transfer scenarios for raw materials and finished products, which require a large number of Heavy-Duty Trucks with high frequency, heavy load, and long-term idle speed. Such scenarios have become the primary target of the government’s environmental protection rectification. On the transportation route outside the factory, there are also scenarios of “railway/waterway mainline transportation + short-distance vehicle feeder”, in which the Heavy-Duty Trucks used in short-distance feeder lines are also could be replaced by BS electric heavy-duty trucks.

4. Port and dock scenario

There are a large number of Heavy-Duty Trucks operating in the state of high frequency, low speed and heavy load within the port. Due to the long waiting time for loading and unloading in the port, the energy consumption and pollutant emissions are relatively high during traditional fuel or gas vehicles’ frequent start or stop and long-term idle speed. The external transport route from the port to the yard also features with high frequency, short distance and fixed route, so it is also suitable for replacing the traditional Heavy-Duty Trucks with BS electric heavy-duty trucks.

5. Urban public service scenario

For short-distance transportation scenarios in cities, including sand and muck transportation for urban construction, concrete mixing transportation, urban sanitation transportation, etc., traditional fuel or gas trucks are noisy, polluting and have high emissions, which have a tremendous negative impact on the urban landscape. Therefore, traditional fuel or gas trucks are suitable to be placed by BS electric heavy-duty trucks in such scenarios.

IV. Comprehensive Promotion: On the Way to Realize Low Carbon and Smart Transportation

Before 2019, the electrification speed of Heavy-Duty Trucks worldwide was slow. After four years of painstaking R&D and market development from 2018 to 2022, SPIC has realized the market and large-scale promotion of electric Heavy-Duty Trucks, so that BS electric heavy-duty trucks have genuinely completed the transformation from being questioned to fully embraced.

1. Achieved periodical achievement

(1) Construction of the ecosystem

SPIC has closely cooperated with vehicle manufacturers, battery manufacturers, suppliers of battery swapping equipment and core components, providers of comprehensive energy service and other partners to jointly carry out product design and development, standard definition, business mode innovation and market development and promotion in an open and co-operative manner, so as to realize the collaboration of the whole industry chain of battery swapping upstream and downstream. The ecosystem synergy mode has led to technological innovations such as the positive development of the entire vehicle of BS electric heavy-duty truck, long-life power battery systems, rapid modular deployment of battery swapping equipment, and catalyzed the development of emerging business forms such as battery lifecycle management and green power trading.

(2) Progress of business promotion

Vehicles: as of the end of 2021, SPIC had promoted more than 12,000 BS electric heavy-duty trucks, delivered nearly 6,200 ones, and the cumulative operation mileage was nearly 47 million kilometers.

Batteries: as of the end of 2021, SPIC had completed the construction of Power Battery Banks with electricity capacity of 1.86GWh, cooperated to develop batteries of different capacities adapted to the various needs of all types of BS electric heavy-duty trucks and requirements in different working conditions and environments.

Battery-swap stations: as of the end of 2021, SPIC had finished location selection and survey for more than 600 stations for battery swapping and planned for a distribution of 70 stations for electricity charging and battery-swap stations across 31 provinces, autonomous regions and municipalities.

(3) Product R&D

In terms of product R&D, SPIC, with joint efforts from battery suppliers, top automobile manufacturers and suppliers of vital parts and components in China, has developed 42 lines of BS electric heavy-duty trucks whose batteries are also mutually interchangeable, and further formed into 176 truck models which can meet the needs of electric powering applications from all aspects in all kinds of high-frequency heavy-load transportation scenarios such as that of electric power plants, seaports, steelworks, mining areas, and urban public transport.

Regarding updates and iteration of the battery-swap stations, SPIC has taken the lead in the product development, design and fast iteration. For users of BS electric heavy-duty trucks, SPIC provides them flexible services with combined forms of “stationed battery swapping + mobile battery swapping” and “charging + swapping batteries” and executes flexible network operation according to different operating conditions.

(4) Building of the IoT

SPIC’s self-developed vehicles and battery intellectual hardware terminals, control system of infrastructures for battery charging and swapping and cluster of cloud platforms have enabled high-quality data acquisition and communication and built up a digital ecosystem of green power transportation based on intellectual hardware of the Internet of things. Up to present, more than 5,000 Heavy-Duty Trucks have been given access to the platform.

(5) Establishment of standards

With current solution, which has succeeded in commercialized promotion in large-scale and in a concerted effort with the industry authorities to push forward the establishment of technic standards for the industry, SPIC has accelerated to set the industry-wide uniform standards for BS electric heavy-duty trucks, battery-swap station construction and swapping battery packs. SPIC and its business partners in the ecosystem have jointly applied for over 200 pieces of patents on core technologies related to BS electric heavy-duty trucks.

As of the end of 2021, a total of 218 models of BS electric heavy-duty trucks had been announced by the Ministry of Industry and Information Technology of China, of which 176 models had adopted the SPIC’s battery swap technical standards, accounting for a market share of 80%.

At the same time, SPIC has preliminarily promoted setting local battery swap standards for commercial new energy vehicles in Inner Mongolia Autonomous Region in northern China, Shandong Province on the east coast of China, and Chongqing Municipality in southwest China, and is helping set Standards of China.

2. Planning for Future Development

(1) Objectives

Objectives for year 2025: SPIC will add momentum to accomplish an aggregate delivery of up to 200,000 BS electric heavy-duty trucks made in conformity with the SPIC battery swap standards, operate a Power Battery Bank holding batteries that carry a power capacity of 64.3GWh altogether, build up a total of 4,000 battery-swap stations to provide service in network operation to the BS electric heavy-duty truck users by the end of the year 2025.

Long- and mid-term objectives: At present, China has 10 million fuel Heavy-Duty Trucks. SPIC plans to replace 3 million vehicles of them which are used in short-distance continuous transportation with BS electric heavy-duty trucks.

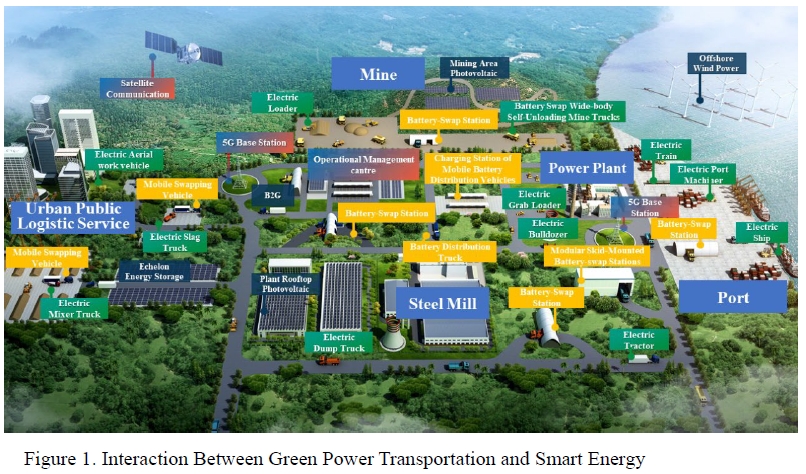

(2) Continued incubation in the extended fields of green power transportation

As it has the BS electric heavy-duty truck technical solutions as a basic platform, developed operation scenarios for green power transportation and arranged infrastructures for battery charging and swapping, SPIC will continue to explore applications in other electricity-powered transportation fields with top priorities in electric ships, electric motors, and electric agricultural vehicles as the major specific fields to be incubated so as to generate scenario-oriented one-stop integrated low carbon solutions in the true senses.

(3) Advancing deep integration of smart energy and transportation industry

Through purchase of green power, integration of Photovoltaic-Energy Storage-Charging, scattered clean energy + intellectual micro-grid and etc., SPIC will propel the deep coupling of clean energy and green power transportation industries leading to exact low carbon emission across the whole energy industry chain from production to consumption.

In such scenarios as mining areas or seaports, scattered power supplies, intellectual micro-grid, energy storage units, infrastructures for battery charging and swapping and etc. are laid out in a way that through supply, storage, deployment and utilization of clean energy, a value chain along the whole process of energy management can be expected to form and green power can be used in BS electric heavy-duty trucks so that exact low carbon emission can be realized in all scenarios.

V. Revolution and Innovation: Coordination of Technological Revolution, Social Benefits and Economic Value

1. Conformity with the warming limit of 1.5 degrees Celsius and the energy development requirements under the “Double-Carbon” policy

Against the backdrop of “Double-Carbon”, high pollution industries, including iron and steel, coal, and chemical industries, are facing potent government regulations, especially the environmental protection index may result in lower corporate ratings, or even production stoppage. BS electric heavy-duty trucks will help traditional manufacturing enterprises with high pollutant emissions and energy consumption to build up a clean energy transportation system. It will adopt the TBS mode to help the enterprises perform well in environmental compliance, avoid closedown of Heavy-Duty Trucks operators in highly polluted weathers, reduce the risk of suspended production due to upgraded environment protection measures and activate stock capacity.

In 2021 August, SPIC and a steel and iron company in Tangshan City of Hubei Province entered into a strategic cooperation to introduce BS electric heavy-duty trucks and intellectual battery-swap stations and promote with all efforts the construction of a clean energy transportation system. These actions will help steel and iron enterprises to succeed in ultra low emission and grade A of environmental performance which will bring them policy benefits including favorable rates of water and electricity, unrestrained production in highly polluted weathers, tax reduction and exemption for purchasing harnessing facilities and environmental protection.

2. Significant cost improvement for Heavy-Duty Truck users

Under the TBS mode, the users of BS electric heavy-duty trucks do not need to purchase power batteries. Heavy-Duty Truck purchase cost is reduced by 50% compared to purchasing one under charging mode with same specification. Therefore, the purchasing cost of a BS electric heavy-duty truck is equal to that of a fuel Heavy-Duty Truck. However, the former does not need engine maintenance or the addition of urea hence a lower operation cost.

Thus, taking into consideration costs of purchasing and energy consumption, BS electric heavy-duty trucks are 15% to 30% more economical than traditional fuel Heavy-Duty Trucks.

3. User friendly

Battery-swap mode of Heavy-Duty Trucks can provide fast power replenishment and has overcome the limited efficiency weakness of Heavy-Duty Truck operation. User experience is remarkably better than the charging mode.

Combined with cloud service platforms and the Internet of things, BS electric heavy-duty trucks are more conducive to users in terms of delicacy management and efficient deployment of operating assets, which enhance corporate business benefits.

Under the battery sharing mode, vehicle users may choose to rent batteries of power capacities according to different working scenarios that could endure traveling the whole route. At the same time, power batteries are operated and maintained centrally by the Power Battery Bank which gives them longer life expectancy and improve their value as a whole across their life cycle.

4. High reproducibility

Heavy-Duty Trucks are popular as a kind of traditional transportation vehicle. BS electric heavy-duty trucks are prone to be accepted since they are not going to cause great changes to existing logistics and transport systems.

The wider use of BS electric heavy-duty trucks requires no demanding changes to existing infrastructures including land and roads while stable electricity supplies and mobile internet support only will suffice the operation of the sold BS electric heavy-duty trucks and battery-swap stations.

It could be concluded that such project of BS electric heavy-duty trucks can be rapidly reproduced anywhere in the world as long as it has short-distanced road transport scenarios such as mining areas and ports together with an enterprise like SPIC who leads and dominates in the promotion of BS electric heavy-duty trucks, construction of Power Battery Banks, planning of battery-swap stations, and set-up of cloud service platforms.

5. Great value of applications in the transport and energy industries combined with big data

Many provinces, autonomous regions and municipalities around China have been planning and developing 5G + Intelligence administration to proactively promote its transformation proactively. Via promoting the network integration of energy, transport and information, SPIC performs real-time capturing and analysis of the production and business information, providing a pool of reliable and useful data for the transportation sector and energy management department to conduct capacity deployment, electricity allocation, and transport infrastructures planning and improvement.

6. High gender-inclusiveness

More than 1.2 million drivers in China are female. The BS electric heavy-duty trucks improve the drivers’ driving experience, significantly reduces their labor intensity, and enhances the dignity of the work thus making this profession more gender inclusive.

The operation of Power Battery Banks and infrastructures for battery charging and swapping requires less labor intensity which enables an easier access for female employees than male counterparts to equal job opportunities to create comparable value.

7. Intense attention and high recognition

As a major promoter in the industry of BS electric heavy-duty trucks in China, SPIC has drawn extensive attention from governments at all levels, media and the public, and received several awards and honors granted by the government and the industry. Several important Chinese media, such as xinhuanet.com and people.com.cn, have had positive reports on the project. At the same time, SPIC plays a crucial role in directing the industry and market incubation in the field of BS electric heavy-duty trucks which is well recognized by the industry.

In order to further improve the new products of BS electric heavy-duty trucks and public recognition of the new mode, SPIC has created access for public participation with openness and transparency, opened the WeChat official account of “SPIC’s Green Power Transportation” to release updates on the product and the industry, and actively attended industry-related exhibitions to listen to proposals and opinions from the public, truck users and industrial partners for continuous improvement and innovation of products and modes.

VI. New Mission, New Momentum

1. Who are we? ——we are different because of the missions we have assumed

SPIC is one of the five major government owned energy enterprises in China and owns businesses in wind, light, water, fire, hydrogen energy, energy storage, coal, aluminum, integrated intelligence energy, etc., especially in wind power and photovoltaic system set-up which is world leading with a coverage of areas. During the thirteenth “Five-Year Plan” period, SPIC put forward the 2035 strategic objective of “building up a world-class clean energy enterprise with global competitiveness”. Guided by the concept of “Innovation, Coordination, Green, Openness, and Sharing”, SPIC is ready to take its social responsibility and becomes the first government owned electricity enterprise in China to announce its timetable to achieve its peak carbon emission by 2023.

In 2021, SPIC announced to officially launch incubation in the field of “Green Power Transportation”, coordinated subordinate enterprises and external collaborators to establish the Green Power Transportation Innovation Center, and also the Green Power Transportation Technology R&D platform and the Green Power Transportation Asset Operation platform of SPIC, responsible respectively for the technological innovation and commercial operation in the field. SPIC is committed to make its green power transportation business the integrator of energy ecosystem using electricity as alternatives and the “mover” of green power.

2. Whom do we want to be? ——a doer to promote global “low carbon transportation”

SPIC has focused its efforts on alternative of electric Heavy-Duty Trucks in the specialized transportation field of “heavy, high frequency”. By 2025, through upstream and downstream industrial corporations, it’s estimated to have a total of 200,000 fuel Heavy-Duty Trucks replaced with electrical power ones which will bring a yearly electricity consumption of 30 billion kwh and a yearly decrease of 9 billion liters of diesel consumption hence 23.67 million tons of CO2 emissions and 159,000 tons of four pollutant emissions can be saved every year.

SPIC will promote the combined achievement of clean energy to replace fossil fuel, economic benefits, environmental benefits and social benefits while seeking to lower business operating costs:

● Push forward intelligent transformation of BS electric heavy-duty trucks: unmanned technology and digitalized platform will direct the development of Heavy-Duty Trucks battery swapping toward intelligence; SPIC is actively pushing forward the building of cloud service platforms for Power Battery Banks, the management of charging and battery-swap stations, and monitoring and mobilization of the Internet of vehicles. Realization of digitalized operational empowerment and asset management will drive high-quality and sustainable development of the Heavy-Duty Trucks battery swapping industry.

● Promote standardization of BS electric heavy-duty trucks: facilitate coordinated innovation across industrial upstream and downstream chains, ensure product Interoperability, and maintain the features of infrastructures at battery charging and swapping stations.

● Promote de-carbonization of BS electric heavy-duty trucks: take advantage of the distributed new energy generation scenarios to facilitate consumption of green power, which also ensure the transportation is “powered by green energy” at source.

● Promote popularization of BS electric heavy-duty trucks: as technological breakthroughs emerge, cost of energy storage and electricity will keep decreasing, the mode will be fully popularized, and BS electric heavy-duty trucks will play an essential part in people’s lives.

In the meantime, the TBS mode will help SPIC promote more applications of Heavy-Duty Trucks battery swap among the SPEC economies and worldwide, making the global community a green home for all.

VII. Appendix: Successful Cases

Case 1: sustainable hazard-free mining of the “Green Lungs” – Beijing Sand and Gravel Transport Project

1. Introduction of model project

Gravel aggregates are fundamental and Irreplaceable materials used in the largest quantities in constructing infrastructures such as buildings, roads, and bridges. Of the 250 million tones annual demand for goods arriving in Beijing, the gravel aggregates account for 100 million tones. Operating of the fuel Heavy-Duty Trucks in high frequency at the peripheral areas of the municipality to deliver gravel aggregates will cause severe pollution to the environment.

SPIC developed a model project in Beijing, a commercial attempt to replace the traditional fuel Heavy-Duty Trucks with new container-type BS electric heavy-duty trucks. This project used intelligent BS electric heavy-duty trucks as basic vehicles to replace the fuel trucks originally to be used in jobs through the process from mining to aggregates processing, from the use of aggregates to waste recovery, and communication transportation on the way from and to the units, thus making the whole supply chain green powered and revitalizing the tailing assets that were otherwise due to be shut down because of environmental requirements.

The project adopted pure electric Heavy-Duty Trucks and conducted innovative experiments with gravel aggregates as main target in green power transportation. Considering the transport distance, transport volumes and timely requirements of gravel aggregates, new energy Heavy-Duty Trucks were operated in the mode of “railway trunk lines + new energy Heavy-Duty Trucks connection” in the model project, complemented by the construction of the first-ever battery-swap stations for Heavy-Duty Trucks in China. The battery charging can be done by 1 hour and battery swapping within 6 minutes, which has greatly improved the utilization efficiency of the new energy trucks. Combined with energy storage devices and making use of peak and valley electricity, the new energy trucks can achieve scientific utilization of electrical resources.

In addition, innovative application of self-developed dedicated container for railway aggregates has fixed the problems of poor road possibility, and floating dust pollution during transportation, making the project the first case of green transportation of bulk materials in China with low emission throughout the process via the mode of “railway trunk lines + new energy Heavy-Duty Truck connection” in the city. This is not only a milestone of a new mode of green transportation of mining and construction materials in Beijing, but also a model set up for other Chinese cities as guidance. As of present, the project has invested in the operation of 3 battery-swap stations and delivered more than 100 trucks.

2. Model effect

(1) Economic benefits

The TBS mode will significantly reduce the invested cost of the users’ first purchase via the approach of “buying the truck and renting the battery”. According to the actual working conditions, batteries of different power capacities can be chosen to suit the exact needs flexibly with improved economy.

TBS mode enables battery swapping within 3 to 5 minutes “without work stopping” in the scenario of highly frequent operations. Compared with charging Heavy-Duty Trucks, it allows more time for jobs operation and increases income. The unloaded batteries can be recharged during valley hours when electricity rate is lower, reducing expenses on electricity and improving the overall economic benefits. Based on integrated calculation, this model project can save 14% of oil and electricity consumption.

(2) Ecological and environmental benefits

As of 2021 June, this model project had invested and delivered nearly 100 new energy pure electric power Heavy-Duty Trucks and 3 intelligent battery-swap stations. In 2020 the total mileage of the BS electric heavy-duty trucks used in the model project amounted to 6.5 million. The analysis of the measured data showed that the project had saved 2.925 million liters of fuels and reduced carbon dioxide emissions by 7,693 tones, making it an important tool for Beijing to “win the battle for preserving the blue sky”.

Case 2: model project of pilot integration of the Internet of vehicles, unmanned driving and green power transportation

1. Introduction of model project

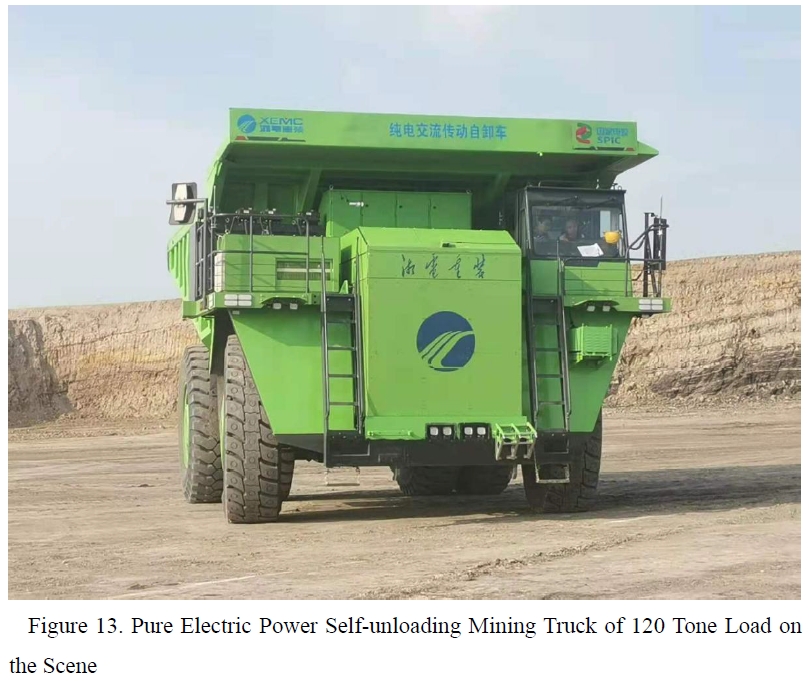

Operating of the fuel mine trucks in high frequency for ore mining and transportation at the open mining areas will cause severe pollution to the environment. A typical open coal mine in Inner Mongolia was chosen for the pilot integration of the Internet of vehicles, unmanned driving and green power transportation, demonstrating the operation of 20 battery swap wide-body self-unloading mine trucks, construction of 1 battery-swap station and small-scale trials of the Internet of vehicles and unmanned driving.

This model project contains battery-swap stations specialized for mine trucks constructed and mainly operated by SPIC which provide the routine service of battery charging and swapping for battery-swap mine trucks. Wide-body self-unloading truck models with a load of 60 tones were adopted in the mine areas and cargo boxes were tailored to the specific needs of the mine scenario. Under different measured gradients, the oil and electricity economy of the battery swap trucks can reach 14%-30%, with excellent power system performance, which can meet the evacuation needs at special mine road conditions and has improved the transportation efficiency significantly.

Additionally, this project invested in the construction of battery-swap stations exclusively for mine trucks in the mining areas. On the basis of standardized battery-swap stations, considering the specialized working conditions of the mining areas, a design of 10 battery pack charging positions and dual-lane was adopted so that when a truck breaks down in the battery-swap station and cannot move, the spare lane can be activated to ensure battery swapping not to be interrupted or hindered in views of the continuous operation of mine trucks.

2. Model effect

From 2020 September to 2021 February, this model project had finished the 5-month live test of battery swap mine trucks. During the test period, the transport volume amounted to 98,500 m³, and electricity consumed was 142,900 kwh, and the number of truck operation reached approximately 3,300 trips. During equipment operation, elevated height was measured 49.01m, average return distance was 7.14km, and the maximum and minimum ambient temperature of the working environment was 27°C and -33°C respectively. The equipment had run steadily and given out favorable test results.

Compared with measured data, battery swap mine trucks hold a strong advantage of better economy over fuel Heavy-Duty Trucks. A standard operating unit includes one exclusive battery-swap station with 10 swapping positions, furnished with nine sets of spare batteries of 422kWh power capacity to serve 20 wide-body battery-swap mine trucks. Under the TBS mode, customers purchase the non-powered truck, rent power battery and purchase the battery swap service from holder and operator of the battery-swap stations. A comprehensive comparison of purchase cost, usage cost and energy consumption cost of a single truck in a single year shows that battery-swap mine trucks can save RMB 454,300 per year than fuel mine trucks, accounting for a comprehensive fuel and electricity saving ratio of 17.03%.

According the working conditions at mining areas that the trucks runs 300 days a year with the average daily driving distance of 246km per truck and a unit fuel consumption of 1.94L/km, if the 300 replaceable fuel trucks in the mine are replaced by electric energy, it is estimated that the annual diesel consumption will be saved by 43,005,700 liters, and the corresponding carbon dioxide emission will be reduced by 113,100 tons, and four pollutant emissions (carbon monoxide, hydrocarbons, nitrogen oxides, particulate matter) will be reduced by 94.41 tons, 19.78 tons, 112.01 tons and 12.26 tons respectively, contributing to the construction of an ecological mine, lowering ecological damage and producing good ecological and environmental benefits.

At the same time, electrical energy alternatives will create a huge market for electricity consumption, which is of great social significance. Based on 300 electric power Heavy-Duty Trucks, this will add 135 million kWh of electricity consumption per year, boosting the electricity consumption market. According to the proportion of clean energy in China’s total energy consumption which was 23.4% in 2019, the corresponding green power replacement scale will be about 31.6 million kwh, effectively promoting the consumption of local new energy power and driving the development of local clean energy industry.