Introduction Video

Introduction

(1) Project background

Papua New Guinea (hereinafter referred to as PNG), is an off-grid economy located in the southwest of the Pacific Ocean. It mainly covers the eastern half of New Guinea island and about 600 nearby islands of various sizes.

PNG is one of the less developed economies in APEC. National education level is generally at a low level, teaching environment and facilities are extremely backward, and the overall educational environment of the economy needs to be improved urgently.

In order to implement the relevant work deployment of the Chinese government and relevant provinces, and strengthen the in-depth exchanges and cooperation with the member economies lie in South Pacific, especially with Papua New Guinea, the Shenzhen Municipal Committee and the Shenzhen Municipal Government decided to assist in the construction of a school in Port Moresby, i.e., PNG and China Friendship School EPC Project (hereinafter referred to as the Butuka Academy). The project has been incorporated into Memorandum of Friendly, Exchange and Cooperation and Plan of Exchange and Cooperation for 2016-2017 signed between Shenzhen and Port Moresby. As the 2018 APEC conference held in Port Moresby, Papua New Guinea, the Butuka Academy is also a gift to PNG from the Shenzhen Municipal Government on behalf of China.

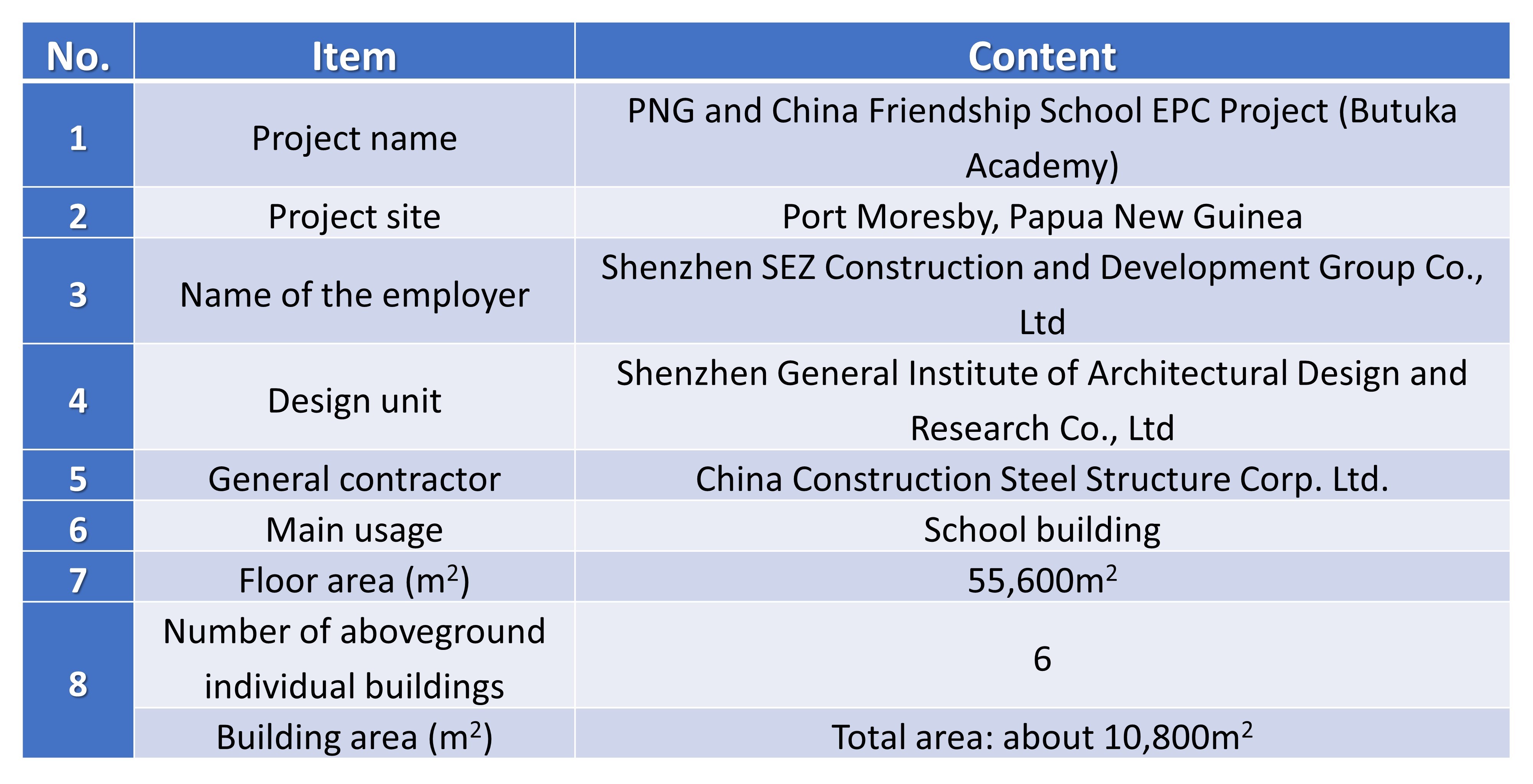

(2) Project introduction

The total land area of the school project is about 50,582m2, and the total building area is about 10,800m2. It is expected to accommodate 2700 students, with 26 classes of primary school, 16 classes of middle school, 10 classes of kindergarten, multi-function halls and 12 staff apartments, as well as outdoor activity sites. The project has a steel frame main structure with three-plate enclosure system. The fire endurance rating and anti-seismic grade should meet the local standards of PNG. The aboveground building has two floors with a building height of 12.45m and there is no underground structure. A total of 20 bus stop pavilions are evenly located at roads of about 10km long, around New Town Hall in National Capital District of Port Moresby (Wageney Road and Senate District) . The project construction is carried out by means of finished product procurement. This project is completed on August 30, 2018.

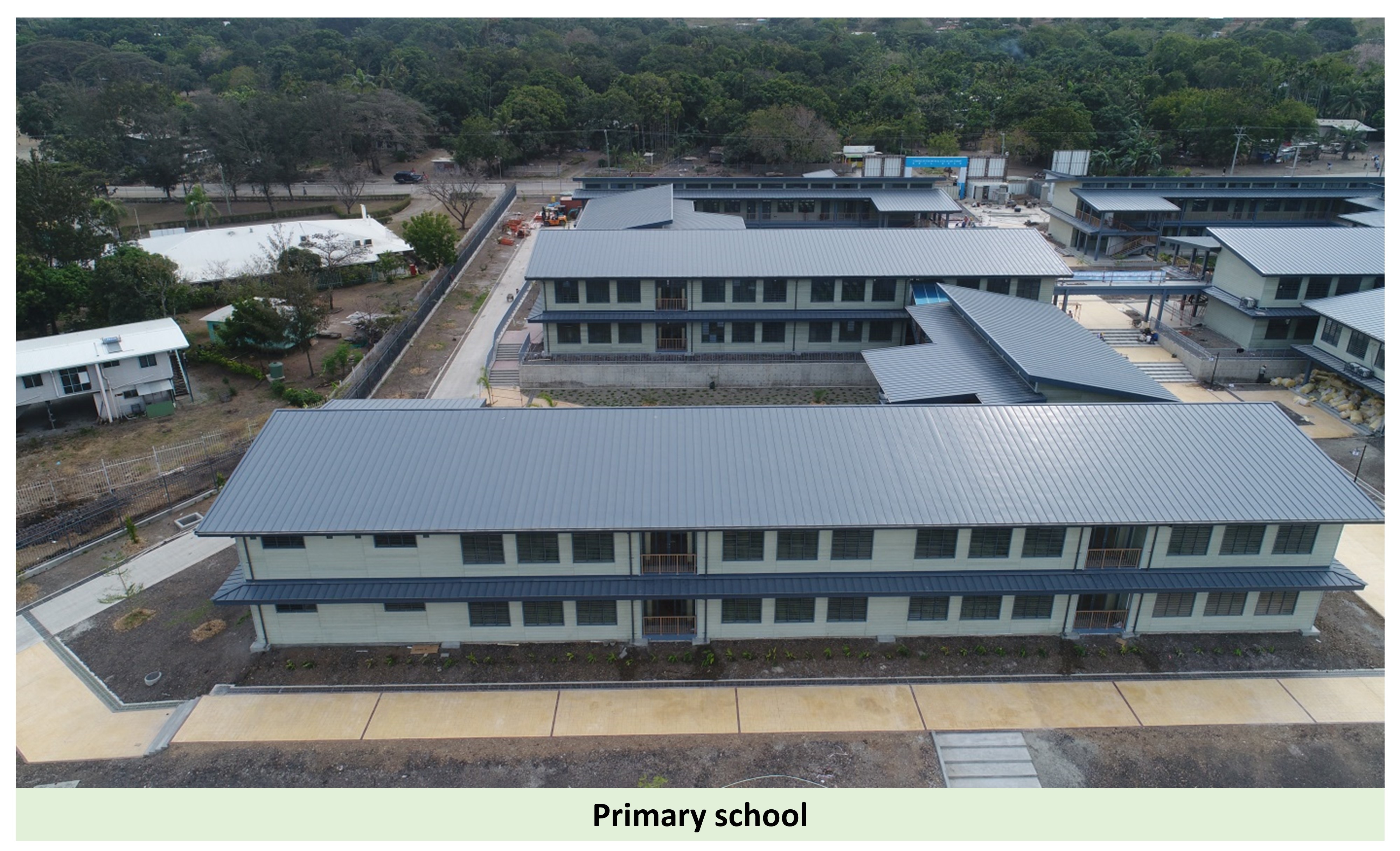

This project has successfully launched the friendly exchange and cooperation program between Shenzhen and Port Moresby, and will be a benchmark of PNG local architecture upon completion.

Innovativeness

1.1 Is the innovation concept come from the project itself or other existing programs?

1.1.1 Innovation point

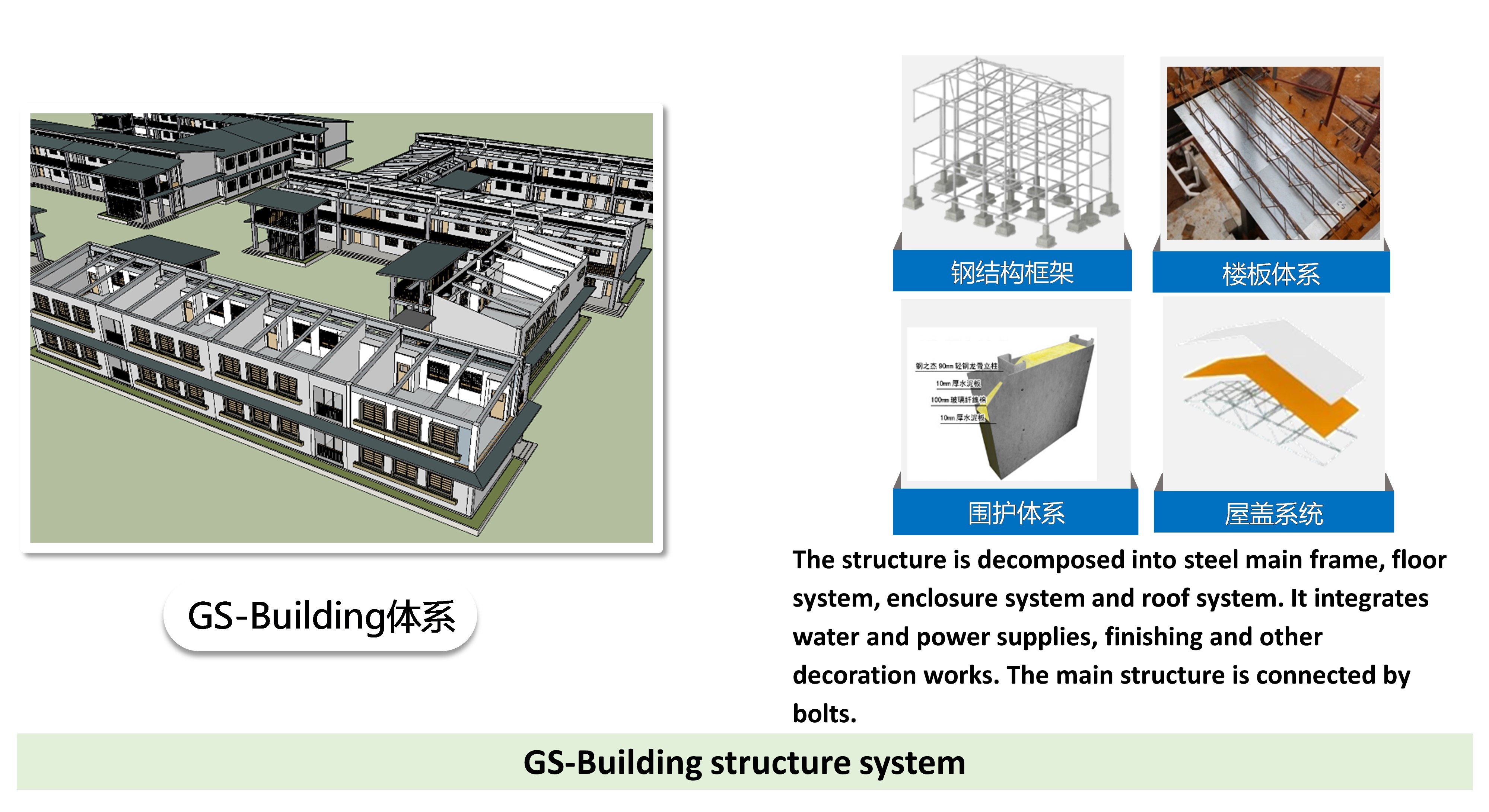

(1) The “GS-BUILDING” prefabricated steel structure building system is adopted as a whole, and it can improve commercialization rate and prefabricated assembly rate of construction parts, solve the problems of low integration, environment pollution, high cost and poor comfort, meet the innovative design concept and green construction requirements of combination with humanities, and stimulate the development of architectural industrialization better.

(2) BIM-based modular construction technology is utilized in an innovative manner. This technology integrates modular design and virtual construction to better adapt to the future Internet + consumer customization era, innovates 3D mapping to solve the problems in integrated manufacturing and installation of parts, and adopts the whole process management based on BIM to solve the problem of information management arising during the construction process.

(3) Prefabricated floor slab with steel rebar truss is adopted. This system boasts the characteristics of high integration, high assembly rate, light weight and strong compatibility with deformation of main frame, and solves the problems of excessive thickness, long construction period and high cost of traditional floor slab.

(4) Prefabricated wallboard with sandwich lightweight steel structure is adopted. This system boasts the characteristics of high integration, high assembly rate and strong compatibility with the deformation of main frame, and solves the problems of excessive weight, poor crack resistance, traditional wet construction method. Besides, it can also reduce the thickness of wallboard and increase the internal usable area.

(5) The materials used for building are manufactured products, which are produced on the factory assembly line in a modular form, and the unit production efficiency is greatly improved. The inner and outer wallboard, roofing and decoration materials are manufactured in factory, and the wet construction on site is reduced by 80%.

(6) Full bolt connection is adopted in key positions of main steel structure, with the assembly rate high up to 80%, and the working efficiency is increased by more than 50%.

(7) The assembly construction method is adopted on site to reduce environmental pollution caused by welding, wet construction, etc. The wall and roof materials can be reused in different places with good economic circulation.

1.1.2 Current situation of lack of local educational resources

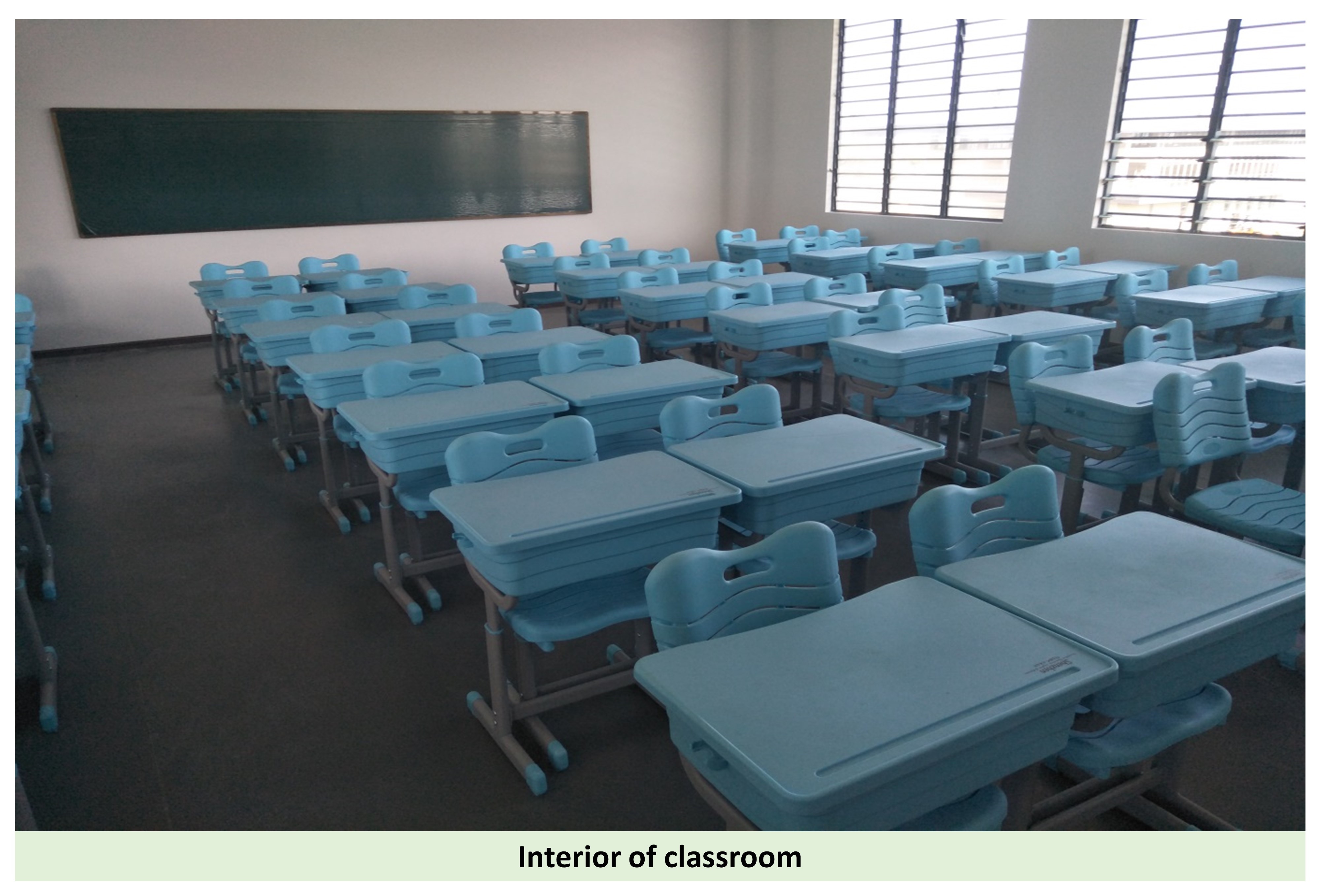

Before the reconstruction of Butuka Academy, there were about 1,500 students and 30 teachers. The numbers of classrooms, desks and other supporting facilities were seriously insufficient, and the teaching conditions were quite poor. Upon completion, the new school is expected to accommodate 2,700 students, including 26 classes of primary school, 16 classes of middle school, 10 classes of kindergarten, multi-function halls and 12 staff apartments, as well as outdoor activity sites. The teaching conditions will be significantly improved, and the shortage of local education resources will be greatly alleviated.

1.1.3 Design concept

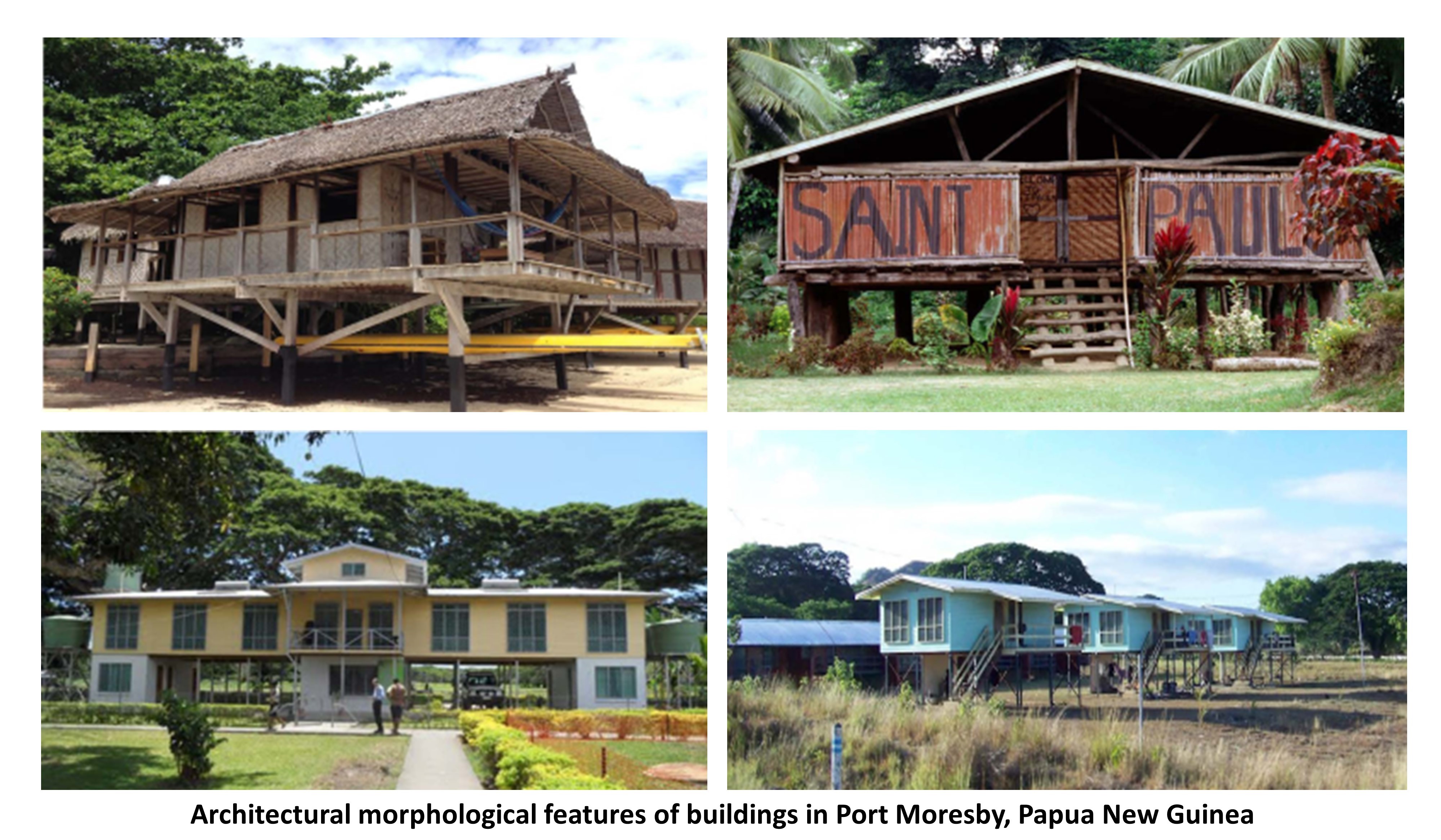

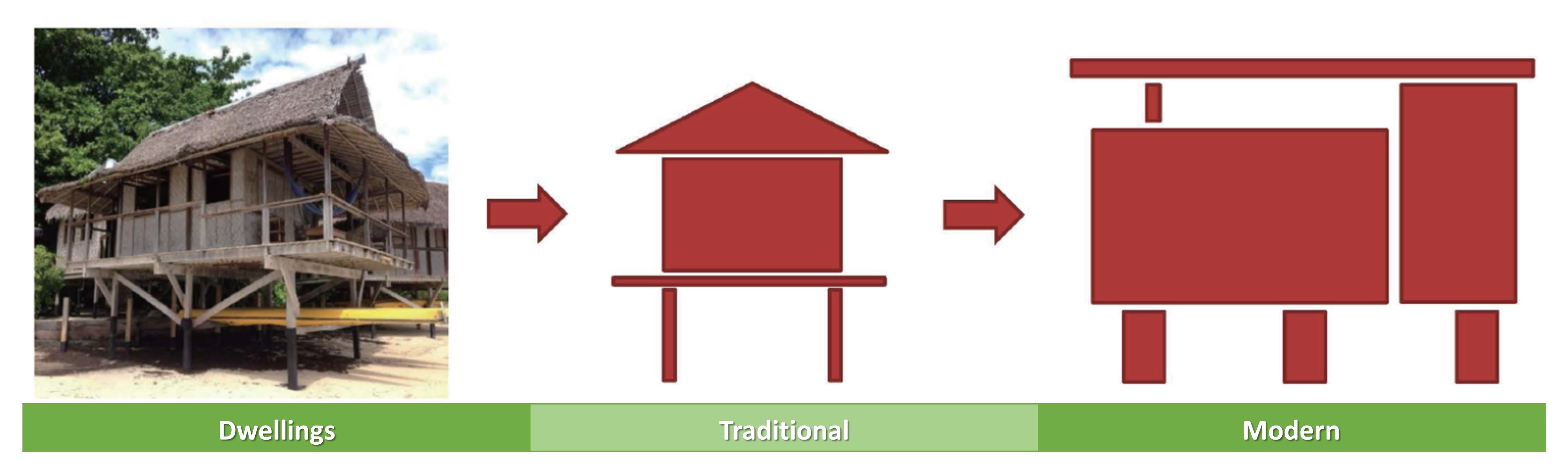

(1) Combine the local traditional architectural morphological features with modern characteristics to meet the needs of local users.

The green assembly building design is carried out after extracting the architectural language of the local traditional buildings according to local climate conditions and site conditions, such as large roof, bottom overhead. Five green technologies, including land saving, energy saving, water saving, material saving and indoor environmental data, are comprehensively applied. Various design strategies are adopted to make the building more ecological and environmental friendly as far as possible on the premise of fully satisfying the building functions and practicability. We not only establish a school, but also bring advanced technology of Shenzhen.

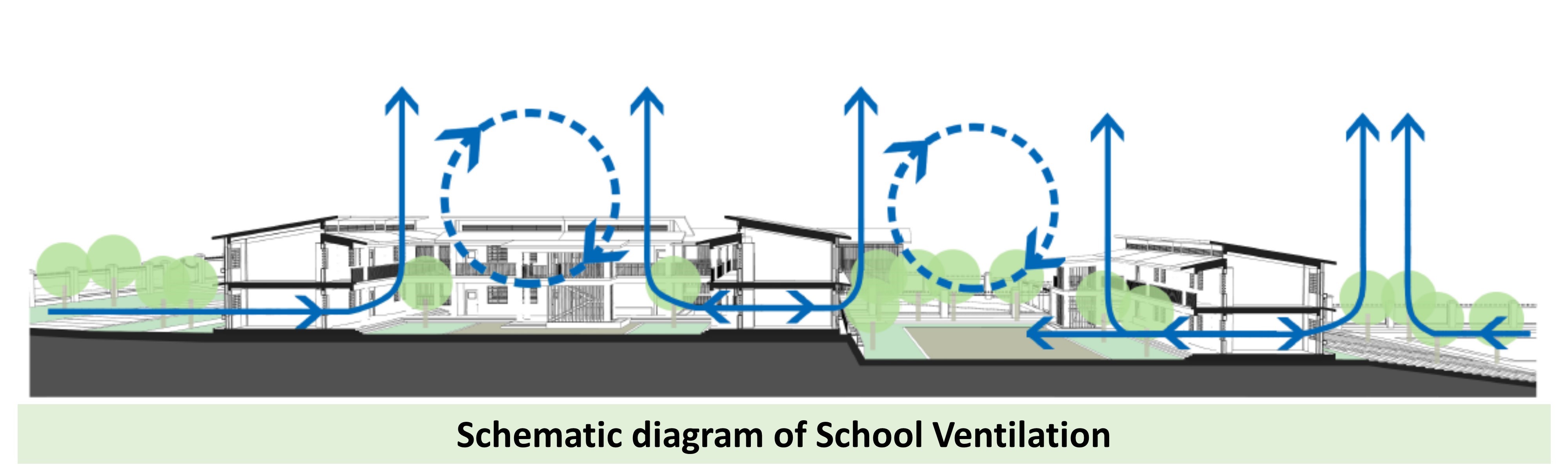

(2) Multi-directional overall function design

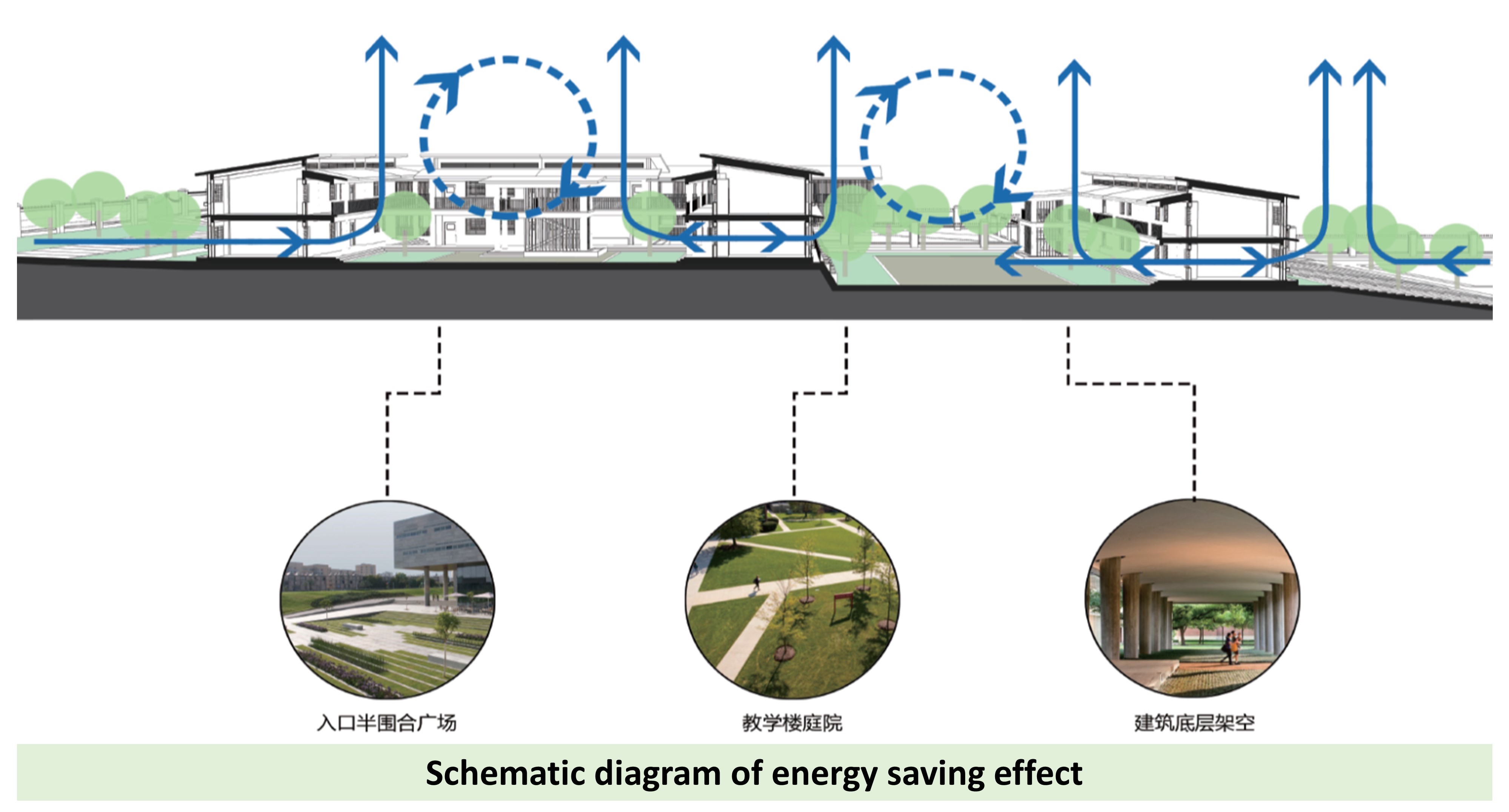

In the design, the sloping roof can effectively shield the direct radiation of the sun to the roof and reduce the heat conduction to the building space; the elevation of the classroom is equipped with high shutters, which can discharge the indoor dirty hot air and suck the outdoor fresh cold air from the lower floor of the building, so as to achieve indoor and outdoor air circulation; at the same time, a natural vertical draft forms in the building courtyard to remove the air and achieve the effect of natural ventilation.

(3) Design of prefabricated building structure

According to the requirements of building industrialization and green building, a modular green building demonstration project with steel structure is built by industrial construction method. The main bearing structure of the whole building product is steel frame, which is composed of prefabricated floor, prefabricated wallboard, prefabricated roof and other prefabricated integrated building components.

1.2 How the innovative policy design encourages financial support and public-private partnership?

1.2.1 Investment situation

The investment and construction mode here is special. Papua New Guinea located on the South Line of the “21st Century Maritime Silk Road” from the South China Sea to the South Pacific Ocean. On June 21, 2018, Chinese President Xi Jinping met with Prime Minister Peter O'Neill of Papua New Guinea at Diaoyutai State Guest House, Beijing. Xi stressed that Papua New Guinea had recently joined the Asian Infrastructure Investment Bank and become the first economy in the Pacific island region to sign a memorandum of understanding with China on the "the Belt and Road" construction. The two sides should take this as a new starting point to actively expand the internal cooperation of the "the Belt and Road" framework and provide strong impetus for the sustained and stable development of bilateral relations. The construction fund of this project is allocated by Shenzhen Municipal Government, but the demand and schedule objectives of the project are proposed by the PNG government and the former school board, which is responsible for the fund supply in the project operation stage. The scale, functions, standards and investment control objectives of the project are determined through communication between the builder and the user. Although the overall goals of both parties are the same, there will inevitably be different interest demands and expectations at the level of sub-goals (investment, progress, scale, standards, etc.), which puts forward high requirements for coordination and control ability of the project management party in the implementation process.

The school board, as the recipient and operator of the school upon construction completion, also provides great help in the process of the school's construction. It not only improves the efficiency of the local construction approval process, offers preferred supply of the municipal water and power resources, but also provides the supply support of greening, human, material and financial resources. This input of local resources is very important for transocean construction aid projects to ensure the progress and quality, and reduce the consumption of unnecessary human and material resources. It also provides experience for such construction aid projects to communicate with the governments and systems in advance that accept the completion and handover, and to bring about benefits.

In addition, as a turnkey project, the project team is organized by the builder for project implementation. During the construction process, many international professional sub-suppliers keep close contact with the bank and are responsible for supply and repayment of construction materials, equipment and construction funds. The off-site assistance brings risks such as unfamiliarity with engineering construction environment (including social environment and natural environment), unsuitability of original supply chain, difficulty in understanding construction culture, inconvenience in front and rear work coordination, etc., which make project communication, progress promotion, quality and cost control more challenging.

1.3 How dose the innovative concept catch the trend of future development?

In order to alleviate the increasingly serious ecological problems, China has put forward the strategy of sustainable development, gradually implemented the work of environmental construction, and put the concept of sustainable development into practice, so that sustainable development becomes the consensus of people. As a typical representative of sustainable development strategy, this project can reduce the use of natural resources and energy, alleviate the current energy crisis, save resources and energy, reduce building energy consumption, and promote the use of renewable energy and other green energy in construction. This project adopts the prefabricated green building system to make the reduction of energy intensity a reality. The concept of prefabricated buildings can reduce the consumption of organic fuel resources with lower combustion efficiency, such as coal, charcoal, etc, rapidly increase the scale of relatively clean energy consumption, including electricity and natural gas, and effectively improve the energy use structure. The improvement of technology level and the increase of innovation investment during the advancement of prefabricated building will often lead to the improvement of energy efficiency and total factor productivity, reduce energy intensity, and further promote new renewable energy sources.

With the acceleration of urbanization process in China, the impact of urban buildings on the environment is also increasing. Taking China as an example, at present, most cities are carrying out construction activities on a large scale and in a large area. The urban ecological landscape is changing rapidly, and a large amount of materials and energy are exchanged between the urban ecological system and the external environment. This project, as a typical green building representative of APEC Economic Leaders’ Meeting can respond to the theme of "high-quality growth and human development" of green energy in buildings, and conform to the inclusive growth goal of sustainable, balanced and coordinated economic development that APEC has been promoting, so as to promote "long-term human development". The BIM model is used in the whole process of the project for process control, which can solve the possible problems in the cradle and play an important role in saving project cost and shortening construction period. This is also in line with the requirement of accelerating the growth of digital economy. From Internet to "Internet +", and then to the digital economy, its development shares the same root and keeps pace with times. The application of construction simulation technology is the representative of emerging technology and advanced productivity, presenting the output and benefit after the overall connection of the whole construction management process of the project. Namely, the application of science and technology is the means, while the digital economy is the result, which can further promote the realization of the strategic goal of scientific and technological development.

Inspiration

1.4 Whether the idea can inspire later/subsequent cases?

(1) Inspiration for the mode of friendly exchanges and cooperation between the two countries

As an important project in Memorandum of Friendly, Exchange and Cooperation and Plan of Exchange and Cooperation for 2016-2017, Butuka Academy will take the school and bus stop pavilion construction as an opportunity to explore a new mode of cooperation, further enrich the content of cooperation, enhance the level of cooperation, promote cooperation in tourism, culture, medical care, education and other fields, build a platform for cooperation and exchanges between enterprises and residents of the two places, achieve win-win cooperation and development, and make a positive contribution to exchanges and cooperation between China and Papua New Guinea. In addition, the project will also guide the two sides to carry out substantive cooperation in port transportation, international education, engineering construction and other fields in the future, promote visits and exchanges between academic and educational organizations, and enhance mutual promotion between the two economies through various channels.

(2) Inspiration for the operation mode of international construction aid projects

The EPC contracting form with large-scale project contractors as the main body provides an effective and feasible mode for the implementation and management of foreign aid projects in energy and resource development, production and technology.

"EPC" is the abbreviation of "Engineering", "Procurement" and "Construction". Engineering includes not only design, but also planning, feasibility study and evaluation, etc.; "Procurement" is not a general procurement of construction equipment and materials, rather, it refers to the procurement of professional equipment and materials; “Construction” involves construction, installation, commissioning and technical training. Therefore, EPC contract conditions are more suitable for engineering projects requiring professional equipment and complicated technology. The preface of Engineering, Purchase and Construction (EPC)/Turnkey Project Contract Conditions by FIDIC recommends such contract conditions, "It can be applied to projects with processing or power equipment, factories or similar facilities provided in turnkey approach, infrastructure projects or other types of development projects". There is a greater degree of certainty about the final price and the required duration of the project. The contractor takes full responsibility for the design and implementation of the project with little involvement from the client. Turnkey projects are usually designed, procured and constructed (EPC) by the contractor, and a fully equipped facility is provided and can be operated “when the key is turned”.

In recent years, with the change of international situation, the ways of aid and sources of funds have been diversified. The introduction of EPC contract conditions for foreign aid projects in energy and resource development, production and technology provides a feasible mode for the implementation of effective management. As a typical EPC international construction aid project, PNG and China Friendship School EPC Project is of great reference significance.

(3) Inspiration for construction of green prefabricated intelligent building

Green construction embodies the concept of sustainable development in the process of engineering construction. Through scientific management and technological progress, it can save resources and protect the environment to the maximum extent, realize the requirements of green construction, and produce green products. With the sustainable development of economy, the construction of transportation infrastructure, urbanization and urban modernization process are accelerating, and all countries are actively exploring the development of prefabricated buildings. However, there are still many problems to be solved. On-site casting is still adopted as the main construction method; the proportion and scale of prefabricated buildings are relatively low; the whole mechanization, industrialization and industrialization of prefabricated concrete structures in the field of housing construction are at a low level; human factors have a great influence on the quality of the project. Compared with the requirements of energy saving, emission reduction, green construction and advanced construction methods, there is still a big gap.

This project is a green integrated building system, which adopts industrialization, integration and modularization construction methods. Compared with traditional buildings, it has obvious advantages in energy saving, water saving, land saving, material saving and environmental protection, specifically, power saving by about 25%, water saving by about 70%, construction waste reducing by more than 50%, work efficiency improving by 30%, and construction space increasing by more than 10%. From the perspective of construction and operation of buildings, the energy intensity has been effectively reduced. As a green prefabricated intelligent building, it can cultivate new industries, promote the development of related industries and enhance the overall level of the construction industry. The successful implementation of the green assembling structure system of the school project can bring reference significance.

(4) Inspiration for improving regional interconnection and inclusive growth

The 26th APEC Economic Leaders’ Meeting takes "grasping the opportunities of inclusiveness and embracing the digital future" as the theme. The topics of the meeting, such as "interconnectivity", "regional economic integration" and "sustainable and inclusive growth", are themselves indicative of the shared vision of the Asia-Pacific economies in the direction of future cooperation. This project, based on “the Belt and Road” initiative, builds an open economy. It is a project that makes great contributions to the education industry on the basis of the common prosperity of the Asia-Pacific economy. This school construction aid project starts from the source of education, improves the driving force of innovation in the future, builds a school platform to provide a basis for sustainable development, enhances people's livelihood and economic exchange from the construction of basic education facilities, and provides conditions for inclusive growth. This is a positive measure to eliminate the development gap, and has certain reference significance for the direction of aid projects.

1.5 What domain has been enlightened by this policy?

(1) Positive role in the friendship between China and Papua New Guinea

(2) Influence on green prefabricated building industry

China Construction Steel Structure Corp. Ltd., the general contractor of the project, actively promotes the continuous development of the green prefabricated building industry and proactively participates in the declaration of invention patents and the compilation of relevant national/industry standards and rules in China, and achieves output of standards. The technology can be replicated and popularized. The specific patent application and standard formulation are shown in Annex 1.

Clearness

1.6 Is there any open and transparent channel of public communication?

(1) The most authoritative local newspaper – post and national publicity platform

The project actively establishes contact with the outside media, relies on the local authoritative newspapers post and national as an external publicity platform, and timely releases major events of the Project Department.

(2) Glodon/ACCOUNT platform

Relying on Glodon/ACCOUNT platform, the EPC general contracting engineering of Papua New Guinea School Project timely releases project progress information and updates. Guanglian Cloud (also known as “Xiezhu”) is a cloud product released by Glodon Company Limited. It takes the project as the core, and connects each team involved in project construction to share project information on a unified platform, so as to complete instant communication and collaboration as well as efficient document review.

(3) Facebook

The Project Department establishes a facebook platform to timely release project developments, communicate and exchange with the public, and absorb suggestions as well as guidance from all sectors of society. Justin W Tkatchenko, the APEC Minister of Papua New Guinea Government, also timely releases project related developments on his personal facebook platform.

1.7 Is there any difference between this policy and other similar policies?

(1) Profound political significance

As a construction aid project between two governments, the Papua New Guinea School project uses a government-dominated construction mode with clear political and social significance. Compared with general social investment projects, this project seeks to maximize the external and public benefits; As an education construction aid work, it not only requires the provision of quality public services and teaching facilities, but also carries the mission of helping Papua New Guinea in education construction and cultural development to achieve overstepping progress.

Therefore, the project set by this construction aid project is related to the urgent need of cultural education for people in construction aid areas. Its target system has strict rigidity with tight construction period, high quality requirements and rigorous investment control, and also the functional positioning of the project is required to be forward-looking with sustainable development capabilities. This requirement has caused risks such as difficulty in coordination of conflicts between construction targets and difficulty in defining construction standards, which brings forward a severe test on project management capabilities and has good social benefits

(2) Green prefabricated architectural structure system

The project’s overall design is greatly forward-looking, and the overall project planning is positioned as a benchmark for schools in the capital area of Papua New Guinea. The layout of the school is scientific and rational, and the teaching facilities are complete. The architectural structure system adopts a relatively advanced green prefabricated architecture system, with high building positioning, new construction technology, high overall assembly rate and low environmental pollution, making this project a top school project in the international education construction aid projects.

(3) Improving local employment rate

As a pillar industry absorbing urban labor, the construction industry has an inviolable position in employment. Due to the industry particularity of construction industry, the general quality of local people recruited is not high. In the process of implementation, the project takes the awareness enhancement of scientific management and the improvement of employees’ quality as the potential driving force to promote the enterprise competitiveness in future development. With the help of government efficiency and the government's regulation and guidance on industrial policies, the project intensifies efforts to train local employees on basic skills, adopts various measures such as “teach, help, and practice” to impart architecture knowledge and skills to local staff, and the effect on improving local architectural skills is significant. Since the start of the project, it has provided a total of 300 jobs for local residents, which has boosted local young adults employment and their work enthusiasm, improved the living conditions of workers, and effectively alleviated the high crime rate of surrounding residents.

Measure

Practicability

2.1 Has any effective measure for moving ahead been made?

2.1.1 Implementation strategy ——rationally designing scheme selection

In the early stage of the project, several design schemes like the three-dimensional modular assembly, traditional reinforced concrete form, and GS-building were compared, and the GS-building form was finally selected. The construction components integration rate and prefabrication rate were high, which solved the low integration level, environmental pollution, high cost, low efficiency and other problems.

2.1.2 Design scheme features and feasibility description

The main body adopts the full bolt connection of steel structure key nodes with high assembly rate and superior performances. The slab construction adopts reinforced truss prefabricated slabs. The system has high integration level, high assembly rate, light weight and strong coordination with the main frame deformation, solving the problems of excessive thickness of traditional slab, long construction period and high cost.

The wall adopts lightweight steel frame system and factory prefabrication field assembly, which has light weight, high strength and good fire resistance, with shockproof, dustproof, soundproof, sound absorbing, constant temperature and other functions. Meanwhile, it also has short construction period, simple construction and high integration, high assembly rate, strong universality and strong coordination with the main frame deformation, solving the problems of excessive weight of traditional block wall, poor crack resistance, wet construction and severe pollution of working environment.

The roofing adopts aluminum-magnesium-manganese metal roofing system, which is modularly manufactured in factory assembly line. The unit production and installation efficiency is greatly improved, the hidden danger of waterproofing is greatly reduced, and the inspection & maintenance are more replaceable. Repeated recycling of steel structure, wall and roofing materials can be realized to save energy material waste and achieve good economic circularity.

This design scheme has great feasibility and architectural reproducibility for overseas construction projects with the rational structure, good overall performance, excellent decoration, energy saving and environmental protection. In addition, the whole GS-building system is lighter than traditional reinforced concrete construction method, which can greatly reduce the basic cost, and the foundation treatment is flexible, which is suitable for areas with various topographic conditions such as mountains, islands and slopes. The maximum elevation drop of building foundation for this project is nearly 3 meters, and the system realizes the component production in factory assembly line with the usage rate of raw materials entering the site close to 90%. Since all components entering the site are completed in factory, only the assembly of components are needed, and there is no need to conduct a large number of mould erecting, concrete casting and masonry operations on site. The error rate is small, the construction waste is greatly reduced, and the comprehensive cost is lower compared with the existing steel-concrete structure which realizes the sustainable development in a real sense. The construction period is much shorter than that of traditional construction methods, complying with industrial policies and investment directions, and meeting the requirements of energy conservation and emission reduction as well as the development of circular economy. Meanwhile, thanks to simple construction and assembly processes, the project can create a number of employment posts, expand the scope of employment, and solve the problem of employment for regional surplus labor. In the process of planning, design, manufacturing and installation services of this project, the standardization, elaboration and customization of construction industry have been actually embodied and proved to be technically advanced and reliable. After the project is implemented, it helps to improve the competitiveness and economic benefits of enterprise and has good social and environmental benefits.

From the perspective of the development path of prefabricated construction, the construction industry will be incorporated into modern industrial system, and many problems existing in the development of prefabricated construction will be solved. The prefabricated construction will rise everywhere, which also provides enterprises in many industries with excellent development opportunities. On the other hand, the development of prefabricated industry will, to a certain extent, drive the regional construction material revolution, which plays a very positive role in accelerating the pace of urban construction, improving the quality of urban construction, and creating the rich and colorful urban architectural styles. The component manufacturing in factory basically realizes dust-free operation, which avoids the dust of site construction, and eliminates the phenomenon of construction disturbance. Regarding energy-saving design, in order to comply with the construction energy-saving standard, traditional construction adopts external wall internal insulation or external insulation for its enclosure structure, but the goal of equal service life for the insulation materials and the construction’s main structure cannot be achieved. The new mobile integrated house provided by this project adopts the veneer baseplate and inner filling of green safety insulation material glass-fiber cotton, which not only meets the requirements of energy-saving standards, but also realizes the integration and equal service life of insulation materials and buildings.

2.1.3 Execution strategy——project analysis and scheme formulation

In order to realize this design system, the project has formulated more than 30 detailed construction schemes for each stage and each professional process, among which there are 9 special programs focusing on requirements of green construction, committed to the achievement of energy saving and material saving during the project implementation process.

Key points and difficulties in construction existing in the project and their countermeasures are analyzed in Appendix II

2.1.4 Measure planning

In view of the key and difficult points of the project construction, analyze the corresponding countermeasures or special schemes, and create the project implementation plan and overall construction deployment. The deployment includes organizational structure selection, clarifying the posts and personnel responsibilities, clear plan of the overall objectives, construction period objectives, quality objectives, safety and civilized construction objectives, fire protection objectives and environmental protection objectives. And it selects the major construction methods, selection of machinery and equipment, construction schedule, general layout, construction process organization. In order to show the sense of responsibility for project quality and the highly responsible attitude of integrity towards the owners, before the project is delivered for use, special course training will be given to the relevant contact person of the local school board in Papua New Guinea, so as to ensure that the Receiving Party can use the advanced teaching facilities and equipment of the school smoothly. During the warranty period, the project department requires that the subcontractors and their suppliers should complete all work needed to repair quality problems or damages. If the responsibility falls to the project department/subcontractor, the cost shall be borne by the project department/subcontractor. After the completion of the project, the post-service work will be carried out by the Department of Commerce of the company. They will communicate with the owners through letters, visits, talks and other forms, so as to understand the opinions and requirements of the owners, reply to the defect repair requirements put forward by the owners in time and repair according to the contract. For the owners' satisfaction, the project manager shall arrange and cooperate with other requirements of the owners, such as the provision of information and relevant inquiries.

2.2 Is there any effective measure for moving ahead been made?

2.2.1 Quantify the overall goals

In view of the specific implementation plan of the project, we carry on the analysis and the quantification control from the design, processing and manufacturing, transportation, installation construction and work schedule control at each stage. Because it is a fabricated building, the roof, wall, structure and other components are designed with the detailed drawings and lists. The component traceability has the characteristics of uniqueness and partial universality, which also allows precise control from the source of materials and reduces waste of materials and energy.

In order to strictly follow the accuracy and rationality of the schedule network diagram, the project has formulated the material use plan and guarantee measures. It is set with a special person to control, and the main equipment are provided with plan and guarantee measures, labor force plan and guarantee, process control guarantee, material input turnover guarantee measures, etc.

Replicability

2.3 Could the ideas, methods or techniques be applied internationally?

The economic composition of a region is a nation group of a region or within a region. The reproducibility of a project is determined by the characteristics of the project and the material, equipment, level of development and transportation conditions of each region,, economy or location. The easier the material is obtained, the more convenient the transportation is and the simpler the production process is, the easier the promotion and replication are. It is not difficult for modern people who have mastered new building materials, processes and techniques to build high-quality buildings. The assembly type is adopted with the industrialized construction mode according to the requirements of building industrialization and green building. The main supporting structure of the whole building product is a steel frame, which is composed of assembled floor, assembled wallboard, assembled roof and other assembled integrated building parts. They are the forms of component that are easy to be processed, with a complete set of technological process. And there are the simple construction and installation process, and varied models, which are conducive to the replication of regional economies.

Cost-effectiveness

2.4 Will it be cost-effective to implement?

2.4.1 Economic benefit

Due to the serious shortage of infrastructure and supporting facilities, dependence on imports of construction materials, complicated procedures of application for construction, poor security, and the lack of engineers and technicians, etc. the project construction cost of Papua New Guinea is generally 2~3 times of that in China. Of which the price of concrete is about 5 times of that in China, mechanical stage class is about 4 times and steel bar is about 4.5 times. Therefore, the dosages of concrete and steel bars in the project are reduced and replacing the traditional form with a new structural forms has become the primary goal of the project.

The self-developed two-dimensional modular assembled steel structure building system is used in the project, with the main cost advantages as follows:

(1) Replace the traditional concrete beam column with steel structure frame

The use quantity of steel structure in Papua New Guinea School Project is 1500t, the quantity of concrete is reduced by 6100 m3 and steel bar is reduced by 650t compared with the traditional reinforced concrete frame structure, with the construction cost reduced by 3.72 million yuan.

|

Framework scheme |

Category |

Unit |

Engineering qty |

Price Per Unit |

Total price (Yuan) |

Total price of the scheme (ten thousand yuan) |

|

I |

Steel structure |

ton |

1300 |

14500 |

18850000 |

1885 |

|

II |

Concrete |

Cubic meter |

6100 |

2400 |

14640000 |

2257 |

|

Steel bar |

ton |

650 |

12200 |

7930000 |

The steel bar truss deck with high integration density and high assembly rate is used on the second floor of primary and secondary schools and teachers’ apartment and the interlayer of multi-purpose hall, with an area of 4600 ㎡, to reduce the workload of formwork and steel bar colligation on site, thus the dissipation of steel bar is reduced by 4.5% and construction cost decreases by 427,800 yuan.

|

Supporting scheme |

Category |

Unit |

Engineering qty |

Price per unit |

Total price (Yuan) |

Total price of the scheme (ten thousand yuan) |

|

I |

Steel bar truss deck |

m3 |

4600 |

310 |

1426000 |

142.60 |

|

II |

Steel bar |

ton |

69 |

12200 |

841800 |

185.38 |

|

Formwork |

m3 |

4600 |

220 |

1012000 |

(3) Replace the traditional masonry wall with sandwich type prefabricated assembled wall panels of lightweight steel joist

The practice of masonry wall in Papua New Guinea is to pour concrete in hollow block; the quantities of construction is reduced by about 2300 m3, including about 1250 m3 of concrete, and the construction cost is reduced by 1.316 million yuan.

|

Wall scheme |

Category |

Unit |

Engineering qty |

Price per unit |

Total price (Yuan) |

Total price of the scheme (ten thousand yuan) |

|

I |

Light partition wall |

m3 |

11200 |

520 |

5824000 |

582.40 |

|

II |

Building blocks |

Cubic meter |

2300 |

1800 |

4140000 |

714.00 |

|

Concrete |

Cubic meter |

1250 |

2400 |

3000000 |

(4) Replace the traditional concrete roofing with Al-Mg-Mn roofing

New short vertical side Al-Mg-Mn roofing system has an area of 12000 ㎡, with concrete consumption reduction of 1320 m3, and construction cost reduction of about 1.068 million yuan.

|

Roofing scheme |

Category |

Unit |

Engineering qty |

Price per unit |

Total price (Yuan) |

Total price of the scheme (ten thousand yuan) |

|

I |

Al-Mg-Mn roofing system |

m3 |

12000 |

455 |

5460000 |

546.00 |

|

II |

Concrete |

Cubic meter |

1320 |

2400 |

3168000 |

652.80 |

|

Protection from Water |

Cubic meter |

12000 |

280 |

3360000 |

Compared with traditional structural system of concrete frame and masonry wall, construction cost of the above assembled structure and short vertical side Al-Mg-Mn roofing system is reduced by about 6.5318 million yuan.

2.5 Is there any measurable reduction of emission or energy use? Please describe the measurement method.

2.5.1 Energy saving and emission reduction benefits

The project adopts a green assembled building structure system, which has many advantages compared with the traditional cast-in-place structure construction:

In terms of labor costs, it uses industrial construction projects, and labor costs will be reduced by about 52%; and the construction period will be shortened by more than a quarter, and the management fees will be reduced by about 25%.

In terms of main materials, turnover materials and consumables, considering the overcapacity of domestic steel structure and the high price of concrete in Papua New Guinea, the project uses a total of 1300t of steel with a cost saving of 3.72 million. The inner frame and template of the turnover material are saved by more than 80%, with the cost saved by 75% and the outer frame saved by more than 85%. Light steel keel wallboard can reduce masonry and plastering projects. Only the foundation and building floor need some in-situ water conservation, with water consumption saving by more than 70% and electricity saving by more than 20%. Engineering material: it adopts much factory processing with small on- site rebar use, saving about 1% of steel.

In terms of green construction, energy saving and emission reduction, the assembly structure is adopted to reduce the generation of construction waste, the discharge of construction sewage, the interference of construction noise, the influence of harmful gases and dust on the surrounding environment, and to ensure more civilized on-site construction, environmental protection and civilized construction. According to relevant data, the construction of per 10,000 square meters in energy-saving indicators is: 430 tons of coal, 3.28 acres of land, reduction of 1280 tons of carbon dioxide emissions, 235 tons of sulfur dioxide, and 2.68 tons of nitrogen dioxide.

2.5.2 Measurement method

For the detection of relevant energy-saving and emission reduction items, the two green technologies of energy-saving and water-saving in green-assembled building design are taken as examples, the rest materials and emission reductions can be compared and calculated according to the completion drawings and the national building construction emission standards, and will not be detailed here.

The sustainable energy conservation embodied in the project is mainly in the conservation of electricity. The average annual temperature in the local area is relatively high, so all the windows in this project are blinds; and the second floor is an inclined roof overhead layer, and a small blinds suction window is placed next to it. The design forms a vertical wind extraction, and the horizontal triangular prism space formed by the flat ceiling of the inclined roof effectively blocks the heat conduction of the roof under the roof insulation effect; Even if the secondary heat enters the roof overhead space, the collected heat can be output to the outside through the side louvers.

Moreover, the opening area of the blinds is close to 100%; and the air interface and the handle pushing distance have great advantages when it is compared with the traditional windows. According to the Chinese Public Building Energy-saving Testing Standard, the building with no centralized refrigeration and air-conditioning system should have a temperature and humidity detection number more than 10% of the total number of rooms, and the temperature and humidity detection method shall meet the following requirements:

1. Temperature and humidity measuring point arrangement principle: 1) Select the temperature and humidity measurement points in the top layer of the first layer; 2) Set the temperature and humidity layout points in the different air distribution.Moreover, the opening area of the blinds is close to 100%; and the air interface and the handle pushing distance have great advantages when it is compared with the traditional windows. According to the Chinese Public Building Energy-saving Testing Standard, the building with no centralized refrigeration and air-conditioning system should have a temperature and humidity detection number more than 10% of the total number of rooms, and the temperature and humidity detection method shall meet the following requirements:

2. The temperature and humidity measurement points should be set in representative positions within the indoor activity area and (700~1800) from the ground. The temperature and humidity sensors should not be affected by solar radiation or indoor heat sources. The number of positions should meet the following requirements: 1) 1 Measuring point when the room usage area is less than 16m2; 2) 2 measuring points when the room usage area is greater than or equal to 16m2 and less than 30m2; 3) 3 Measuring points when the room usage area is greater than or equal to 30m2; 4) 5 Measuring point when the room usage area is greater than or equal to 60m2 less than 100m2; 5) The measuring point should be added one every increase of (20~30)㎡ for room usage area is greater than or equal to 100 m2;

The indoor average temperature and humidity should be calculated according to the standard formula, and the data is detected by the third-party testing unit. The traditional building can be selected as the reference, make same measurement counting for measurement calculations; The final temperature difference will be converted into heat. According to the technical parameters of the air conditioner manufacturer, the power output corresponding to the cooling temperature difference in different use areas can be obtained for 10% power saving.

The water saving of this project is reflected in the sloping roof confluence, organized drainage to the green belt and the grading layout technology. This technology can save irrigation water. In the countries where PNG is only divided into dry season and rainy season, it can form obvious large-area greening effect. The local drinking water resources are scarce. Many local households cannot afford to pay for tap water according to our survey, and most of them use natural water from river ditch. The school's water source is municipal water supply, so it is crucial to save water and reduce emissions in such a large green area.

Two detection ports for each courtyard of each unit of buildings can be selected; and there is a drainage ditch near each detection port, and the rainwater discharged from the organized outlet will be drained into the flexible container of the drainage ditch, and the flow accumulation amount of 1h/1h/2h/3h/single rain time in rainy season in will be collected. Such amount of water is the amount of water saved in the responsibility area of each water outlet in the green area. The sum of the municipal water supply energy consumption and the irrigation demand energy consumption calculated according to relevant standards is the water saving energy consumption (except for labor costs).

The heat transfer coefficient detection, non-transparent and light-transmissive outer structure heat transfer performance of the project, fresh air volume detection can be more intuitively detected by relevant equipment according to relevant standards, and it will not be detailed here.

Consistency

2.6 Are adopted measures consistent with energy policy and strategy?

2.6.1 It is consistent with prefabricated building policies of national development

In recent years, prefabricated buildings have been well developed in China, which successfully solves the problems of low construction efficiency, high cost and environmental pollution. They have the characteristics of low construction cost, fast construction speed and little impact on the surrounding environment. In the implementation process of the project, according to the needs of school buildings, green assembly-style architectural design is adopted to continuously improve the school building needs, and give full play to the functional characteristics of the school public buildings, thereby improving the efficiency of the building. With the needs of industrial construction in various countries, developed countries regard the manufacture and assembly of building components as an important symbol of industrial modernization. The assembly system structure is an important embodiment of the world construction industry. The implementation and application of prefabricated buildings is a reform of the construction industry that promotes the development and innovation of the construction industry. The prefabricated building system gives full play to the functional advantages of the building. The building model is low-carbon and environmentally friendly, which can improve the seismic performance, environmental protection effect and energy-efficient production structure of the building. The ion model is in line with the concept of energy conservation advocated by current society. Under this efficient building system, the project has led to the formation of a good momentum of “government promotion, enterprise participation, and prefabricated building development” within the PNG.

2.6.2 Reduce the energy intensity of the APEC area

On one hand, the World Energy Supply Center presents a diversified development trend. On the other hand, the world's energy demand continues to maintain a steady growth trend. The Asia-Pacific region is more prominent as a world energy demand center. Meanwhile, the political and economic situation, energy market fluctuations, and climate change factors, public perception and acceptance also have a major impact on energy policy development in the Asia Pacific region. In addition, energy costs play an important role in the competitiveness of high-energy industries in the region. In order to promote sustainable development, APEC economies face enormous challenges as well as new opportunities. PNG is located in the South Pacific traffic fortress and has important strategic significance in the South Pacific region. However, the industrial development in the PNG countries is lagging behind. Through the successful implementation of the green prefabricated buildings of the Papua New Guinea School project, a benchmark building has been formed in the area for learning. It can greatly promote the development of the local green building industry, which will lead to immeasurable environmental and energy benefits for the Papua New Guinea and the entire South Pacific region.

2.7 Is there any long-term measure or implementing organization for this project?

2.7.1 Process decomposition plan

According to the actual construction of the project, according to the structural form of the building and the characteristics of the construction environment, the project department will carry out the rational process decomposition of the assembled building. The ideas and decomposition are as follows:

|

No. |

Thought |

Specific requirements |

|

1 |

Reasonably arrange the work on the critical lines and the overlap between the key tasks. |

The work duration of the critical lines determines the construction period of the construction process. Reasonable arrangement of key work and reasonable arrangement of the overlap between key tasks is the core content of controlling the construction progress and preparing the construction schedule. |

|

2 |

Reasonably arrange the insertion time of work on non-critical lines. |

In the schedule arrangement, consider inserting as early as possible for work on non-critical lines to provide more spare time. Otherwise, once the work on the non-critical line is delayed and the delay exceeds the free time difference, the non-critical line will turn into a critical line, which will inevitably lead to delays in the total construction period. |

|

3 |

Take full account of the necessary technical intervals. |

In the schedule arrangement, the technical interval time of each process and the previous process should be fully considered to avoid that it cannot be transferred to the next process in time according to the plan requirements due to previous process, resulting progress blind area. |

|

4 |

Fully consider the time required for construction preparation such as supply and production cycle. |

In the schedule arrangement, the length of the work duration shall fully consider the time required for the construction preparation of the work. |

Overall progress node arrangement during the construction phase:

|

Construction stage |

Overall construction schedule |

|

Ground and foundation construction |

(1) Construction time: August 07, 2017 to December 11, 2017, a total of 127 days. (2) Considering the large earthwork volume of the project and non-ideal underground soil quality, the earthwork time can be appropriately extended to ensure the accuracy of the overall schedule. (3) The project is divided into five working areas, and each unit is a construction area. In order to save the construction period, each unit adopts the construction idea of excavating from the periphery to the center with simultaneous support. First, it will make construction on temporary construction area, the kindergarten construction area, and the primary school, then the teacher's apartment and the multi-purpose hall area. (4) Foundation construction shall be in accordance with the construction sequence of earthwork excavation. |

|

Ground steel structure and floor construction |

(1) Construction time: October 24, 2017 to December 29, 2017. (2) After the completion of the foundation construction, it will make construction of the above-ground structure. The structural construction sequence is to first install the steel column and install the steel beam. After steel structure installation, the roofing system will be installed, and then the floor slab formwork support system will be set up. After the splicing of the formwork is completed, the reinforced truss slab will be poured, and finally the inner wall and the outer wall system will be installed. |

|

Roofing project construction |

(1) Construction time: November 03, 2017 to March 05, 2018. (2) After the construction of the steel structure main body, the installation of the roofing system will be started, creating conditions for the construction of the interior wall panel and the decoration. |

|

Wall and electromechanical construction |

(1) Construction time: November 25, 2017 to May 20, 2018. (2) After the construction of electromechanical installation project, separate commissioning inspection and acceptance will be carried out, and then the interactive debugging acceptance will be carried out. Meanwhile, the data collection and arrangement of each major will be carried out to create conditions for completion acceptance and data delivery. |

|

Outdoor construction |

January 12018 to July 10, 2018. |

|

Start materials project |

April 16, 2018 to July 30, 2018. |

|

Completion acceptance |

July 21, 2018 to September 30, 2018. |

2.7.2 Planned Implementation Measures and Implementing Units & 2.7.3 Analysis of Influencing Factors

|

No. |

Influencing factors |

Specific analysis |

|

1 |

Human factor |

(1) Causes such as insufficient number of on-site managers, lower capabilities of local construction and management, improper arrangement of taking working days off may lead to adverse effect on project progress. (2) Causes such as insufficient number of on-site workers, insufficient number of constructors on the site or workers not backing for work timely on important holidays may lead to adverse effect on project progress. |

|

2 |

Mechanical factor |

(1) Mechanical failure: Failures of crane, forklift and ground pump during the construction period will affect the normal construction. (2) Mechanical approach: Exit or replacement of machines etc. caused by untimely mechanical approach or relaxed approach acceptance will lead to adverse effect on project progress. |

|

3 |

Material factor |

(1) Material reserve: Insufficient material supply may occur during holiday and construction peak periods, so the failure of preparing the corresponding material reserves in advance will affect the progress of the project. (2) Component materials transportation: This project is located in Papua New Guinea, of Oceania. Most of the component materials are transported by sea for long distance, so the material purchase, processing and other factors of component are related to the smooth progress of the project. (3) Material plan: Problems (Time delay, wrong quantity etc.) of material approach caused by untimely submission of material plan or improper preparation of material plan will affect the progress of project. |

|

4 |

Process factor |

(1) Weather factor: Material and technology etc. are affected by weather in construction, the local weather in Papua New Guinea is divided into dry and rainy seasons, so rainy and hot weather will influence the construction to a certain extent. (2) Technical factor: Both the construction deployment and arrangement, division of flow section, connection of each process and construction technology will have a great influence on the construction progress. |

|

5 |

Safety factor |

Safety rectification takes up the construction period, and a major safety incident can even lead to work stoppages. |

|

6 |

Quality factor |

Quality rectification takes up the construction period, and a major quality problem even leads to work stoppages. |

|

7 |

Social security factor |

External security situation may influence the construction, including burglary, material theft and so on. |

2.7.4 Targeted Long-term Guarantee Measures

|

No. |

Content |

Guarantee measures |

|

1 |

Personal guarantee |

(1) Select persons with similar engineering management experience to form EPC Project Department of Papua New Guinea School, ensure that the general contractor managers comply with the requirements of the owners and have related experience, so as to make sure that the project manager and all constructors and technicians can be competent for their own positions. (2) Set up positions according to the characteristics of project and the need of management process, ensure the responsibilities of functional management, professional management, process management and regional management are clear and can be distributed to each person. (3) Conduct territorial management and select a local and professional subcontracting company with strong power investigated by our company. Such kind of subcontracting company is a local engineering company with considerable strength in Papua New Guinea that can ensure the adequate labor force and has already reached a considerable scale, which can guarantee the adequacy of labor resource of this project. |

|

2 |

Mechanical guarantee |

(1) Prepare the mechanical approach plan for the subsection construction, supervise the whole process of mechanical equipment from approach to exit, and ensure all the mechanical equipment can be approached in time. Make sure the timely and regular maintenance can be achieved in the construction process, and the construction can be carried out smoothly. (2) Two 25t lifting equipment and two forklifts are purchased as material transportation equipment for the project. The method of selling for rent is adopted to meet the requirements of construction machines on the site. At the same time, strictly control the local professional subcontracting and timely allocate the machinery and equipment to meet the needs of the site. Set up a mechanical management team composed of different personnel at different stages according to different areas to ensure the normal operation of machinery and timely maintenance in case of any failure. (3) The professional subcontractors is required to prepare an appropriate equipment approach plan, and urge their equipment to approach the site in time and maintain the equipment according to the requirement of general contract. |

|

3 |

Material guarantee |

(1) Make use of the group purchasing advantage of the company in construction market, and take advantage of its own revolving material reserves such as the key structural raw material like steel plate, and other materials on other site that can be uniformly deployed by the company. (2) Adopt segmented control for the whole process from the bidding to exit of engineering and turnover materials, so as to ensure the timely supply and quality of materials, and further ensure the construction quality and safety. (3) Mobilize the existing well-established materials distribution network and those contract-honoring, trustworthy and powerful material sub-suppliers to ensure the timely supply of materials for the project. (4) Prepare a resource needs plan. Prepare a detailed general plan, monthly plan and weekly plan for the materials used and make reasonable and optimized adjustment of plan and timely preparation to ensure the timely approach and meet the needs of construction. (5) The project tester shall timely test the materials approached, and submit the test result or product testing certification to the local consultant engineer in time, so as to avoid the delay of construction due to quality issues of materials. (6) The professional subcontractors are required to prepare the corresponding materials approach plan according to the general progress plan, and supervise the timely approaching of main materials. |

|

4 |

Technical guarantee |

(1) Adhere to the concept of “Technology first”. Hire a locally accredited consultant company to review the technical practices of project, and solve process problems. Establish an expert team at the company level for the project to provide technical and management support. (2) Organize scientific and technological research, carry out technical research on structural deformation control, steel structure measurement, and steel structure welding construction, etc., to provide technical support to ensure the construction period; (3) Prepare related technical document before manufacturing the structures and carry out technical assessment in accordance with local specifications, to ensure the processing progress and product quality. (4) Prepare the transportation in advance, make sure the custom declaration of structures can be carried out smoothly and the structures can be approached in time. Reasonably arrange the approaching sequence of structures to avoid the accumulation and reduce secondary transportation. Carefully check the structures during the process of outside hoisting, and make sure all the structures are hoisted in order. (5) Formulate a detailed structure installation sequence on the construction site, so as to avoid the mutual interference during the installation. |

|

5 |

Fund guarantee |

(1) Formulate a fund use system to ensure that the construction progress will not be delayed due to poor capital turnover. |

|

6 |

Management guarantee |

(1) Establish a sound plan guarantee system, prepare safe and civilized construction plan for different stages and formulate an implementation-oriented quality assurance framework, so as to make sure the progress of project is practically carried out according to PDCA cycle and the project quality is strictly and effectively controlled, and further ensure the safety of construction. (2) Implement reward and penalty system for progress plan, safe and civilized construction of on-site projects, quality assurance, etc. (3) Establish a sound finished product protection system, and uniformly coordinate the work of finished product protection of subcontractors, in order to avoid the rework due to improper protection and influence on construction period. (4) Conduct on-site layout design according to different construction stages, so as to ensure the good order of plane management, and avoid the reduction of work efficiency due to improper plane management. |

|

7 |

Guarantee of Internal and External Relations |

(1) Enhance the communication with owner, designer and consultant unit, and ensure the smooth progress of the work. (2) Enhance the communication with local related government agencies of Papua New Guinea, and ensure the smooth development of the work. (3) Enhance the coordination with social public relationship, and coordinate the relationship with the original school board, police in the construction area, surrounding residents and village committees, so as to create superior external environment for the normal construction. |

Performance

Completeness

3.1 Is the achievement scale measurable?

At present, all the completion acceptance and handover procedures have been finished for the project of Papua New Guinea school, the summary of scientific and technological achievements of assembled buildings in Papua New Guinea has been organized and two scientific papers have been prepared as well.

3.2 Will it make a considerable success in project goals?

This project is progressed according to the planned schedule. At present, the project has been completed and passed the completion acceptance of local functional departments and the handover of school management committee. What’s more, the welcoming ceremony for the leaders of China and Papua New Guinea was held during the period of APEC conference. The prefabricated buildings have higher installation and construction efficiency than those of traditional concrete projects and short maintenance time after installation, so the next use process can be initiated immediately, which makes the total construction period of prefabricated building short, and the material, energy, material and financial resources consumed in the whole construction period are greatly reduced. Due to the simple process and obvious interface division of prefabricated building structure, the effective accounting can be carried out from the procurement and transportation of various professions to the installation and construction, the work efficiency of each process can be accessed in the whole cycle, and then the overall project can be better controlled. This is also why the project can be still completed with good quality on schedule and smoothly handled over within so short a construction period and relatively poor environment and construction conditions.

Verifiability

3.3 Is there any data presented to support the project? & 3.4 Is there any supportive measurement or reference for the provided data?

(1) Economic achievements

1. Prefabricated structure and low edge aluminum magnesium manganese roofing system can bring direct economic benefits from reducing project costs. The price of building material in Papua New Guinea is higher, but the project can fully return the price advantage of domestic materials by using such kind of prefabricated structure. Shipping from China to Papua New Guinea will greatly reduce the cost increase caused by the purchase of local materials in Papua New Guinea.

|

Economic benefit analysis of structural optimization |

|||||

|

No. |

Name |

Content |

Unit |

Reduced principal amount |

Remark |

|

1 |

Frame |

Steel structures |

Item |

372 |

/ |

|

2 |

Support |

Truss deck |

Item |

42.78 |

/ |

|

3 |

Partition wall |

Light steel keel partition wall |

Item |

131.6 |

/ |

|

4 |

Roof |

Aluminum magnesium manganese roofing system |

Item |

106.8 |

/ |

|

5 |

Total |

/ |

/ |

653.18 |

/ |

2. On-site workers can increase their productivity by up to 50%, the per capita labor rate increases by 35%, and the construction time is saved by 30%. The site is mainly installed with components, and the production efficiency has been greatly improved. Compared with traditional cast-in-place concrete construction method, it can not only significantly save the manpower and material resources, but also shorten the construction period. Moreover, the constructors are also changing from “Outdoor workers” to industrial workers focused on “Factory manufacture”, breaking through the traditional construction method affected by engineering work surface and climate. Thus, batches of product can be repeatedly manufactured in the factory, and "all weather" production in four seasons can be achieved, which is a typical example of “trading the time by space”.

3. Except the foundation, the project is constructed with prefabricated components. All the key positions of steel structures are connected with screw bolts, and the partition wall is also changed from the traditional masonry to the light steel keel collection glass fiber cotton with external gypsum board and cement fiber board. As a result, the size of each part of the floor meets the design requirements at one time without repair, which represents the core concept of “Architectural quality space” of Chinese architecture. At the same time, due to the high flatness of light steel keel prefabricated wallboard, it is feasible to cancel the traditional plastering and leveling process and directly apply putty and emulsion paint, in order to reduce the cost.

4. Compared with traditional construction method, the prefabricated structure construction has many kinds of advantages such as integration of design, production and construction, fast construction speed, high construction quality, improved construction environment, improved seismic resistance and so on.

(2) Energy conservation achievements

According to the daily production statistics of project department, compared with conventional projects, the project achieves a true sense of "zero" timber consumption except for a small amount of supporting wood; at the same time, it also reduces the water consumption for concrete maintenance. Compared with traditional construction method, the water consumption per square meter of building area of industrial construction method is reduced by 65%, the wood consumption is saved by 76%, the investment of traditional steel pipe frame is decreased by 70%, and the land and labor are decreased by 37% and 55%, respectively.

The integrated and prefabricated building model will change the on-site workers to industrial workers, which can improve the working environment and condition of workers and increase the labor productivity. The mature model of residential industrialization will definitely reduce the on-site labor force, transform the labor-intensive enterprises into technology-intensive enterprises, effectively improve the technical content of construction projects and change the extensive management into intensive management. Furthermore, the industrialization is able to not only reduce the material and labor consumption, improve the comprehensive quality of buildings, but also achieve the efficiency of energy conservation and emission reduction. This construction mode will become the development direction of construction industry in the future.

(3) Environment protection achievements

Compared with traditional construction method, the assembled structure can save wood and water consumption by 76% and 53%, reduce the noise level and real-time PM2.5 by 25% and 36%, and decrease the sewage disposal and rubbish by 64% and 75%, respectively, which has obvious effect of green economy, energy conservation and emission reduction.

Impact

3.5 Will it make a significant change in the field of energy efficiency and energy saving?

According to the technical requirements on land, energy, water and material conservation, indoor and outdoor environmental quality and operation management of “Green Building Evaluation Standard” (GB/T 50378-2014), and “Green Industrial Building Evaluation Standard” (GB/T50878-2013), it is preliminarily judged that the project can meet the requirements for the number of three-star projects of green building construction based on the recommendations of the current status of project, and the pre-evaluation conclusions are shown in the table below.

|

Evaluation index |

Land conservation and outdoor environment |

Energy conservation and energy use |

Water conservation and water resource use |

Material conservation and material resource use |

Indoor environment quality |

Construction management |

Operation management |

|

|

Control item |

Evaluation results |

Satisfied |

Satisfied |

Satisfied |

Satisfied |

Satisfied |

Satisfied |

Satisfied |

|

Rating item |

Weights wi |

0.13 |

0.23 |

0.14 |

0.15 |

0.15 |

0.10 |

/ |

|

Applicable total score |

100 |

100 |

100 |

100 |

100 |

100 |

/ |

|

|

Actual score |

63 |

85 |

72 |

83 |

90 |

85 |

/ |

|

|

Score of Qi |

63 |

85 |

72 |

83 |

90 |

85 |

/ |

|

|

Bonus |

Score of Q8 |

10 |

||||||

|

Control item |

Satisfied |

|||||||

|

Total score |

82.27 |

|||||||

|

Green building level |

★★★ |

|||||||

(1) A detailed investigation and determination of noise sources inside and outside the environment and building has been made for the project before the planning design, including the comprehensive considerations on the division of functional areas, setting of greening and isolation belts, utilization of favorable terrain and building shielding, anti-noise spacing of buildings, choice of orientation and layout of planes.

(2) In order to improve the urban ecological quality and environmental quality of greening landscape, the green coverage rate of project is as high as 60% or more, and the roof and wall greening technologies are also pursued, which can not only increase the greening area, improve the role of greening in the fixation of carbon dioxide, but also further strengthen the insulation effect of roofs and walls. At the same time, the reasonable use of multi-layer greening including arbor, shrub and grass can reduce the gradual increase of urban and residential temperature and climate dryness, reduce heat island effect and regulate the microclimate.

(3) In order to increase the conservation of rainwater and groundwater on the site, improve the ecological environment and strengthen the underground infiltration capacity of natural precipitation, the area of permeable bricks in the school of this project is up to 7000㎡, and the area of laying permeable bricks in the school of Papua New Guinea is in the leading position. The setting of sufficient permeable bricks is conducive to replenishing groundwater, and able to reduce the ground subsidence caused by falling groundwater levels, decrease the load on municipal drainage system, reduce the peak runoff of rainwater and improve the drainage.

(4) Prefabricated green building is adopted for the internal building structure of school, steel structure frame and thermal insulation materials are utilized for the main body and maintenance system, which can effectively reduce the emission of dust, harmful gas and greenhouse gas, etc. Parameters such as building shape coefficient, external wall heat transfer coefficient, window-wall ratio, curtain wall shading coefficient and shading method meet the scientific setting standard, and the green energy conservation and environmental protection concept has created a precedent in Papua New Guinea.

3.6 Will it impact multiple operational areas or just single specific area?

As the first educational public welfare project of China to provide assistance in construction of Papua New Guinea, EPC general contracting project of Papua New Guinea school has received the attention and expectation of the people of Papua New Guinea since the commencement. With the continuous advancement of the project, its more advanced concept and construction technology of prefabricated green building have attracted a large number of peers in Papua New Guinea to investigate and learn. Based on the major political significance of this project, it is believed that the related practices and experiences of energy conservation, environmental protection and emission reduction of this project will have far-reaching impact on Papua New Guinea and the entire Asia-Pacific region. In additional, as the first educational public welfare project of China to provide assistance in construction of Papua New Guinea, this project will become the benchmark for local school buildings after the completion of construction. This is a major measure of education aid between countries, which will drive the output of developed countries from underdeveloped countries, developed regions to underdeveloped regions, and educational resources to countries with poor educational resources to a certain extent, improve the global cultural education ecosystem, and promote the development of human civilization.

Savings Narrative:

The self-developed two-dimensional modular assembled steel structure building system is used in the project that the dosages of concrete and steel bars are reduced and replacing the traditional form with a new structural forms, with the main cost advantages as follows:

(1) Steel structure frame is used to replace the traditional concrete beam and column. Compared with the traditional reinforced concrete frame structure, the concrete consumption is reduced by 6,100 m3, the steel consumption is reduced by 650t, and the cost is reduced by 3.72 million yuan.