The Green Mark scheme in Singapore has set one of the most stringent M&V (Measurement and Verification) standards for chiller plants and chiller efficiency regime in the world. It has also mandated submission of three-yearly audit for chiller plant performance.

The intent of this legislation is to ensure that building cooling systems are audited to meet minimum energy efficiency and continue to be operated efficiently throughout its life cycles. It is best served if the process is autonomous and continuous to

I. Improve effectiveness and create awareness on operating chiller plant efficiency

II. Empower building managers to maintain plant efficiency through timely alerts via an online portal that collect chiller system’s data, thereby enabling:

a. Machine Learning and base-lining

b. Trend Analytics to spot performance or cooling load variance and sensors' drift

Monitoring by itself does not save energy – it must triggers an action. This portal will give building managers and their nominated contractors the means to be proactive in operating their chillers as smart technology is used to autonomously send out alerts when performance deviation is detected. They will also have online access to the portal to view their portfolio of buildings and compare trended data.

Savings Narrative

As part of the Building Control (Environmental Sustainability Measures for Existing Buildings) Regulations 2013, mandatory energy efficiency audit reports of the central chilled-water plant are required to be submitted every three years to verify that the central chilled water plants in both new and existing buildings continue to operate efficiently throughout their life cycle.

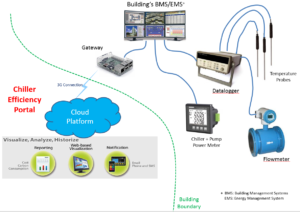

Periodic audit has its limitation, resulting in a saw-tooth pattern of step-wise adjustment at the end of every audit cycle. The intent of the Periodic Energy Audit is thus best served if the process is autonomous and continuous via an online portal. The pilot “Chiller Efficiency Smart Portal” uses Microsoft Azure IoT service and will involve 30 buildings of various types including commercial, retail, institution and hotels.

Monitoring by itself does not save energy, it must trigger an action. Faulty temperature sensors manifest themselves in drift of temperature reading, and worn-out equipment cause efficiency to drop. These deviations are tell-tale signs that will be detected by the portal and alerted to the Facilities Manager (FM). He/she may set specific performance baseline for each building and filter rules that are used to compare against actual performance to calculate potential energy waste or to raise alert so that pre-emptive actions can be taken. Baseline can either be fixed, or derived from past pattern in which the portal learns from a selected period of operation.

With this portal, BCA's Green Mark Scheme is taking a step forward from a 3-yearly rating tool into a dynamic tool to help sustain high energy performance of green buildings regularly. With easy access to comparisons of chiller plant performance trends across multiple buildings, stakeholders can make quick and insight-based decisions on scheduling preventive maintenance, and to negotiate performance-based contracts with their chiller providers. In other words, continuous commissioning of chiller plants empower buildings, big or small, to take ownership of operating their chiller plant efficiently.

Strategy

The Green Mark scheme in Singapore has set one of the most stringent M&V (Measurement and Verification) standards for chiller plants and chiller efficiency regime in the world. It has also mandated submission of three-yearly audit for chiller plant performance.

The intent of this legislation is to ensure that building cooling systems are audited to meet minimum energy efficiency and continue to be operated efficiently throughout its life cycles. It is best served if the process is autonomous and continuous to

I. Improve effectiveness and create awareness on operating chiller plant efficiency

II. Empower building managers to maintain plant efficiency through timely alerts

via an online portal that collect chiller system’s data, thereby enabling:

a. Machine Learning and base-lining

b. Trend Analytics to spot performance or cooling load variance and sensors' drift

Monitoring by itself does not save energy – it must triggers an action. This portal will give building managers and their nominated contractors the means to be proactive in operating their chillers as smart technology is used to autonomously send out alerts when performance deviation is detected. They will also have online access to the portal to view their portfolio of buildings and compare trended data.

Measure

Singapore’s Building and Construction Authority (BCA) has been championing the green building movement in Singapore and has introduced its BCA Green Mark rating scheme. Green Mark is a building rating system designed for the tropics and sub-tropics and with a strong focus on the actual energy efficiency of building systems. Central chilled water plants are commonly used to provide cooling for commercial buildings and there are very stringent, but straightforward, pre-requisite requirements to achieve a Green Mark rating level for these systems, as shown in the table:

|

Green Mark Rating |

Peak Building Cooling Load (RT) | |

| <500 RT | ≥500RT | |

| Minimum Design Annual System Efficiency (kW/RT) | ||

| Certified | 0.8 | 0.7 |

| Gold | 0.75 | 0.68 |

| GoldPLUS | 0.7 | 0.65 |

| Platinum | 0.68 | 0.65 |

Further, As part of the Building Control (Environmental Sustainability Measures for Existing Buildings) Regulations 2013, mandatory energy efficiency audit reports of the central chilled-water plant are required to be submitted every three years to verify that the central chilled water plants in both new and existing buildings continue to operate efficiently throughout their life cycle.

Periodic audit has its limitation, resulting in a saw-tooth pattern of step-wise adjustment at the end of every audit cycle. The intent of the Periodic Energy Audit is thus best served if the process is autonomous and continuous via an online portal. The pilot “Chiller Efficiency Smart Portal” uses IoT service and will involve 20 buildings of various types including commercial, retail, institution and hotels.

Monitoring by itself does not save energy, it must trigger an action. Faulty temperature sensors manifest themselves in drift of temperature reading, and worn-out equipment cause efficiency to drop. These deviations are tell-tale signs that will be detected by the portal and alerted to the Facilities Manager (FM). He/she may set specific performance baseline for each building and filter rules that are used to compare against actual performance to calculate potential energy waste or to raise alert so that pre-emptive actions can be taken. Baseline can either be fixed, or derived from past pattern in which the portal learns from a selected period of operation.

Performance

The portal includes a suite of productivity tools that enables users to select, analyse and download chiller performance data conveniently. For a selected building and selected period in the calendar, the following are easily accessible with a web browser from a PC or a mobile device:

a) Daily cooling load profile

b) Frequency of cooling load occurrences

c) Chiller plant efficiency profile

d) Scattered plot of chiller plant efficiency versus cooling load

e) System level heat balance plot

f) Editable copy of energy audit report (in BCA-prescribed format)

g) List of event and alert log

The dashboard is designed to be user friendly and intuitive. Upon login, users can view all the buildings under their care. Headline numbers are condensed in one page and critical information, such as system efficiency and alarm status, are highlighted as shown below.

|

|

| Dashboard of the Chiller Efficiency Smart Portal | Chiller Plant Performance |

Another notable feature of the portal is a standard data interface based on REST API to facilitate connection to the portal regardless of Building Management System and network.

With easy access to comparisons of chiller plant performance trends across multiple buildings, stakeholders can make quick and insight-based decisions on scheduling preventive maintenance, and to negotiate performance-based contracts with their chiller providers. In other words, continuous commissioning of chiller plants empower buildings, big or small, to take ownership of operating their chiller plant efficiently.

BCA is currently reviewing the Green Mark for Existing Building criteria. Under consideration is a scheme for a Green Mark certified building to be recognised for sustained performance in the area of energy and water efficiency, operations and management, and indoor environment quality. Re-certifying buildings has the option to use this chiller efficiency portal – a dynamic tool that continually testify that its cooling system performs as rated. It is an opportunity to reframe Green Mark recertification to be more market friendly and relevant, beyond a momentary 3-yearly assessment.